OPERATING PROCEDURES

6-13

Models C709 & C717

Operating Procedures

6

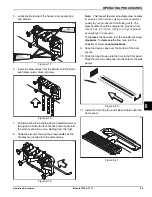

5.

Return to the freezer with a small amount of cleaning

solution. Using the black brush, clean the rear shell

bearing at the back of the freezing cylinder.

Figure 6-42

6.

Repeat steps 1 through 5

for the other side of

Model C717.

7.

Wipe all exterior surfaces of the freezer with a clean,

sanitized towel.

10014

Summary of Contents for C709

Page 8: ...1 4 TO THE INSTALLER Models C709 C717 To the Installer 1 Notes...

Page 36: ...5 16 USER INTERFACE Models C709 C717 User Interface 5 Notes...

Page 50: ...6 14 OPERATING PROCEDURES Models C709 C717 Operating Procedures 6 Notes...

Page 56: ...8 4 TROUBLESHOOTING GUIDE Models C709 C717 Troubleshooting Guide 8 Notes...

Page 58: ...9 2 PARTS REPLACEMENT SCHEDULE Models C709 C717 Parts Replacement Schedule 9 Notes...

Page 62: ...10 4 LIMITED WARRANTY ON EQUIPMENT Models C709 C717 Limited Warranty on Equipment 10 Notes...

Page 66: ...11 4 LIMITED WARRANTY ON PARTS Models C709 C717 Limited Warranty on Parts 11 Notes...