11

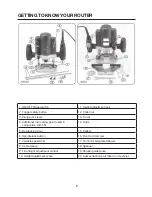

SETTING THE CUTTING DEPTH (Figs. 6-8)

With a suitable router bit fitted place the router on to the work

piece. Rotate the turret (M) to the lowest position. Slowly

plunge the router until the bit just touched the work piece.

Lock the router in this position with the plunge lock level.

Ensure the height adjustment lock (N) is not tight and lower

the rod (O) until it touches the turret.

If necessary turn the fine height adjustment control (P) to

align the nearest digit on the scale against the pointer (Q).

Take note of the setting before raising the rod upward

to set the plunge depth (the difference between the two

measurements) and securely tighten the height adjustment

lock (N). E.G. scale reads 23. After adjustment reads 33, the

plunge depth will be 10mm. Release the plunge lock level

and raise the router back to full height. Rotate the turret

round several positions and the router is set up ready to

begin work.

When beginning to cut, plunge the cutter slowly to the first

depth and proceed with the cut. Take a second pass at

the next step down on the turret and continue until the full

depth is achieved.

Regulate the depth of the cut and speed of feed to ensure no

strain is put on to the cutter or motor, however if the speed is

too slow burn marks may appear on the work piece.

NOTE:

The direction of rotation is marked on the metal

casting above the spindle stop mechanism. Traveling along

a work piece in the wrong direction will cause the bit to pull

and bounce, leading to a poor finish and possible damage.

If, after the full depth has been routed, further material

removal is necessary lock the router in the plunge position.

Rotate the fine height adjustment control (P). Turning the

fine adjustment (P) anti-clockwise will increase the plunge

depth. One complete turn is equivalent to 1mm plunge

depth. When set take another pass along the cut.

NOTE:

Remove the plug from the socket before carrying

out adjustment, servicing or maintenance.