55

Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

ATCR / ATCRL / GAICR / GAICR 300

Maintenance

Lubrication

To reduce the wear caused by the friction caused by the moving parts of the equipment,

it is necessary to carry out a proper lubrication, as indicated below:

1) Every 24 hours of service, lubricate every grease fitting.

• Be sure about the lubricant quality in relation to its efficiency and purity, avoiding the

use of products contaminated by water, dirt or others.

• Remove the remainder old grease around the articulations.

• Clean the grease fittings with a cloth before inserting lubricant and replace the

damaged ones.

• Introduce enough amount of new grease.

• Use medium consistency grease.

2) The lubrication of the roller bearings should be done in the same aforementioned

period (24 hours).

2.1) The roller bearings with oil bath works in constant lubrication, but it is still necessary

to give them the following attention:

• In a flat place, check the oil level of each bearing before using the disk harrow for the

first time and every day of the first week.

• Then, start to check weekly.

• Change all the oil every 1,000 operating hours.

• Use SAE 90 mineral oil only.

2.2) DMO bearings do not need maintenance.

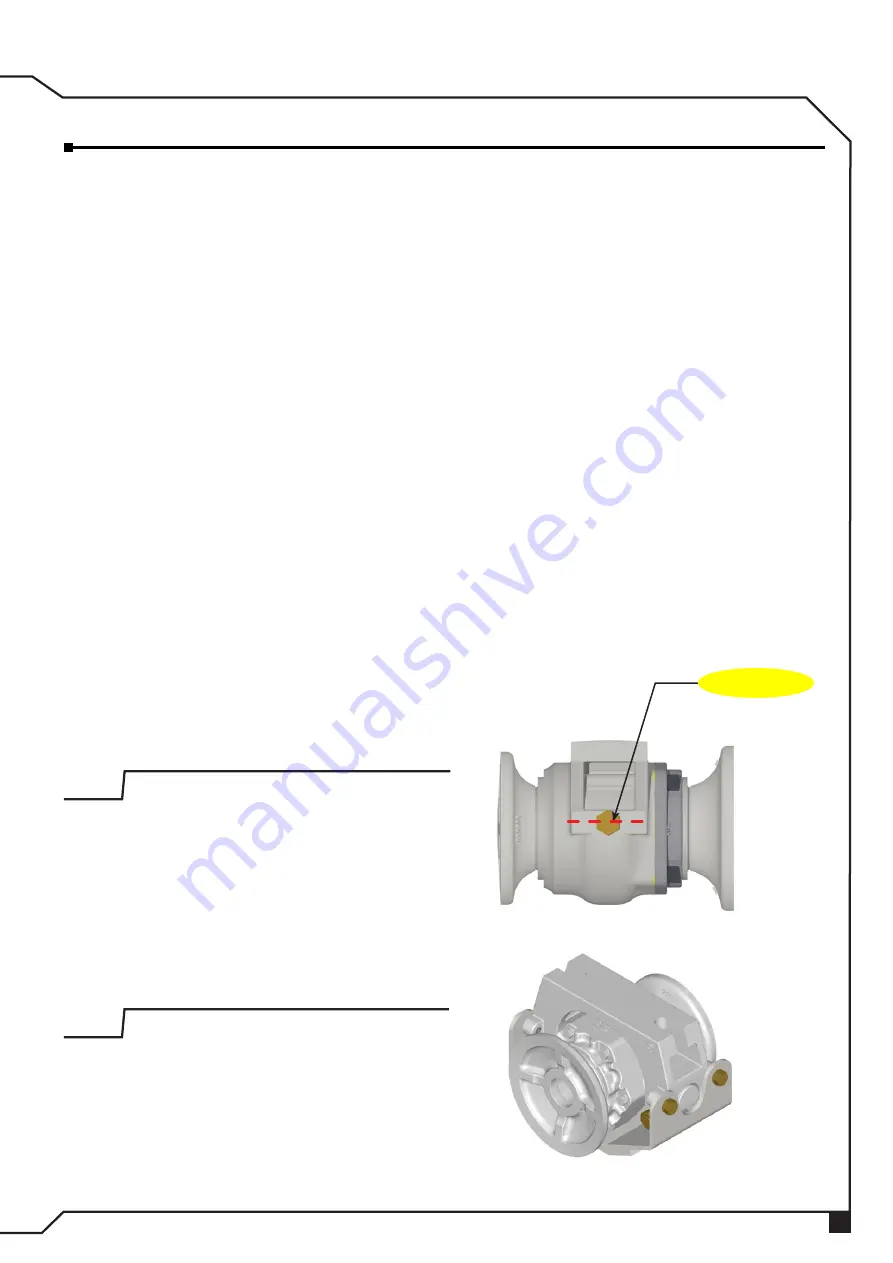

The suitable level is when the oil

reaches the hole of the plug, being

the disk harrow in a flat place.

The oil volume on the DM bearings is

190 ml (except for the ATCRL model,

which volume is 110 ml).

NOTE

Duromark steel-plated bearing.

Assembled with a high-performance

lubricant, the Duromark steel-plated

bearing do not have a plug since

there is no need to refill it, avoiding

the risk of mixing incompatible

lubricants.

NOTE

Ideal level

Ideal level