VERTICAL TOWED MIXER - TWO AUGERS

MV-30D SERIES

MAINTENANCE OPERATIONS

Maintenance operations should be carried out by the mixer user

The following are the basic maintenance operations that must be performed by the

mixer user:

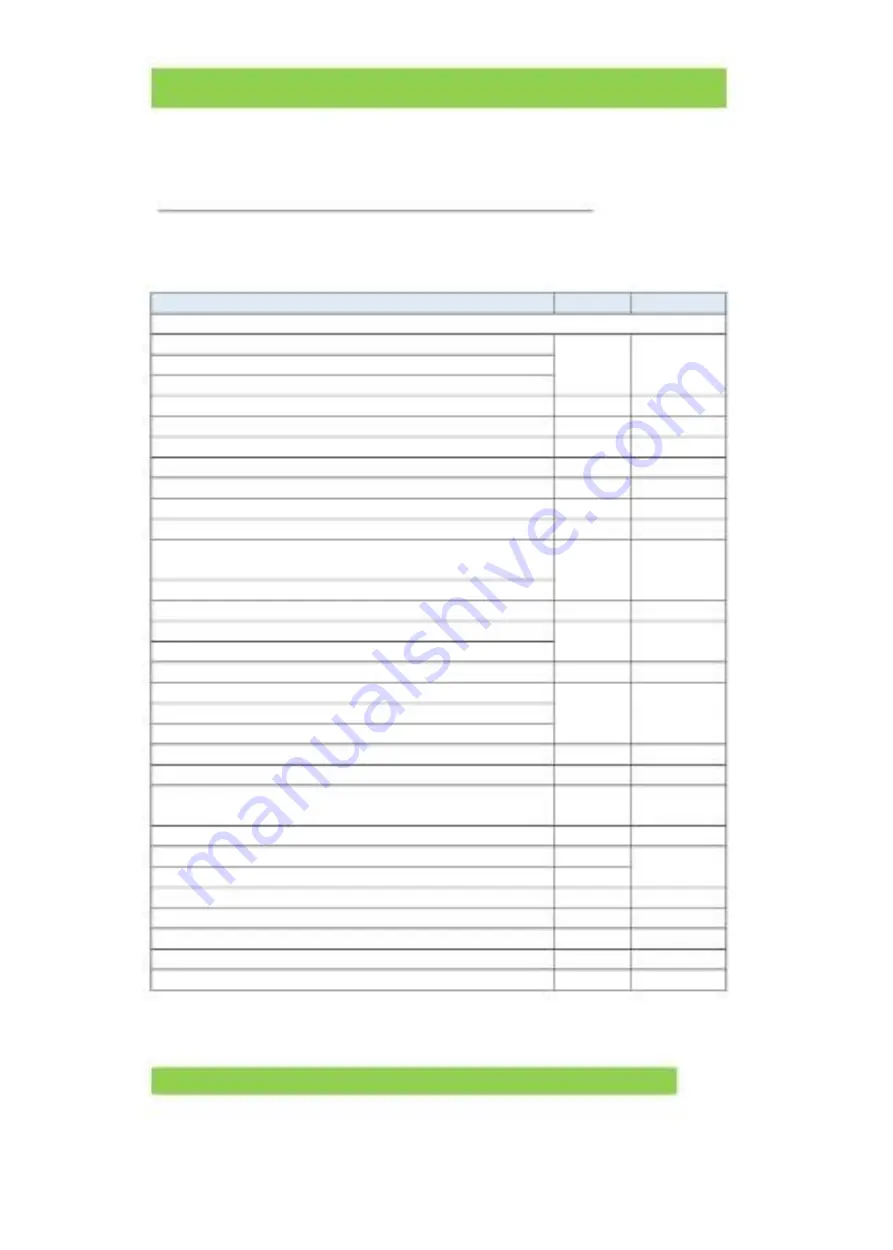

Maintenance operations

Checking levels

Check hydraulic oil level

Check auger redactor oil level

Check 2-speed gearbox oil level

Grease

Grease the indicated points

Filters

Control the clogging of the hydraulic circuit filter

Wheels and tires

Check the tire pressure

Check the tightness of the wheel bolts

Check for the presence of embedded objects in the tire

thread

Check for cuts or cracks in the tire sidewalls

Battery

Check the condition of the terminals

Control the electrolyte level and battery charge

Tub & Auger

Check wear of auger blades

Check the tightness of the bolts in the auger blades

Cleaning the interior of the tub

Unloading conveyor

Cleaning of the unloading conveyor

Check & adjust the tension of the chain in the unloading

conveyor

Hydraulic installation

Visual control of the hydraulic hoses

Visual control of leakages

Check the tightness of the hydraulic hose clamps

Electrical installation

Checking the lighting & signaling system

Checking the scales

Calibration of the scales (1)

(1) The calibration of the scales should be done by TATOMA

Tatoma Ag Equipments Corp. Located in Colcord, OK. Phone (918) 422-4271

First

Periodicity

15 hours

Weekly

Weekly

Daily

Weekly

Monthly

Weekly

Start-up

Quarterly

Monthly

Weekly

Monthly

Weekly

Quarterly

Weekly

Monthly

Yearly

- 65 -