TALOS ITR-T250

9

www.talospos.com

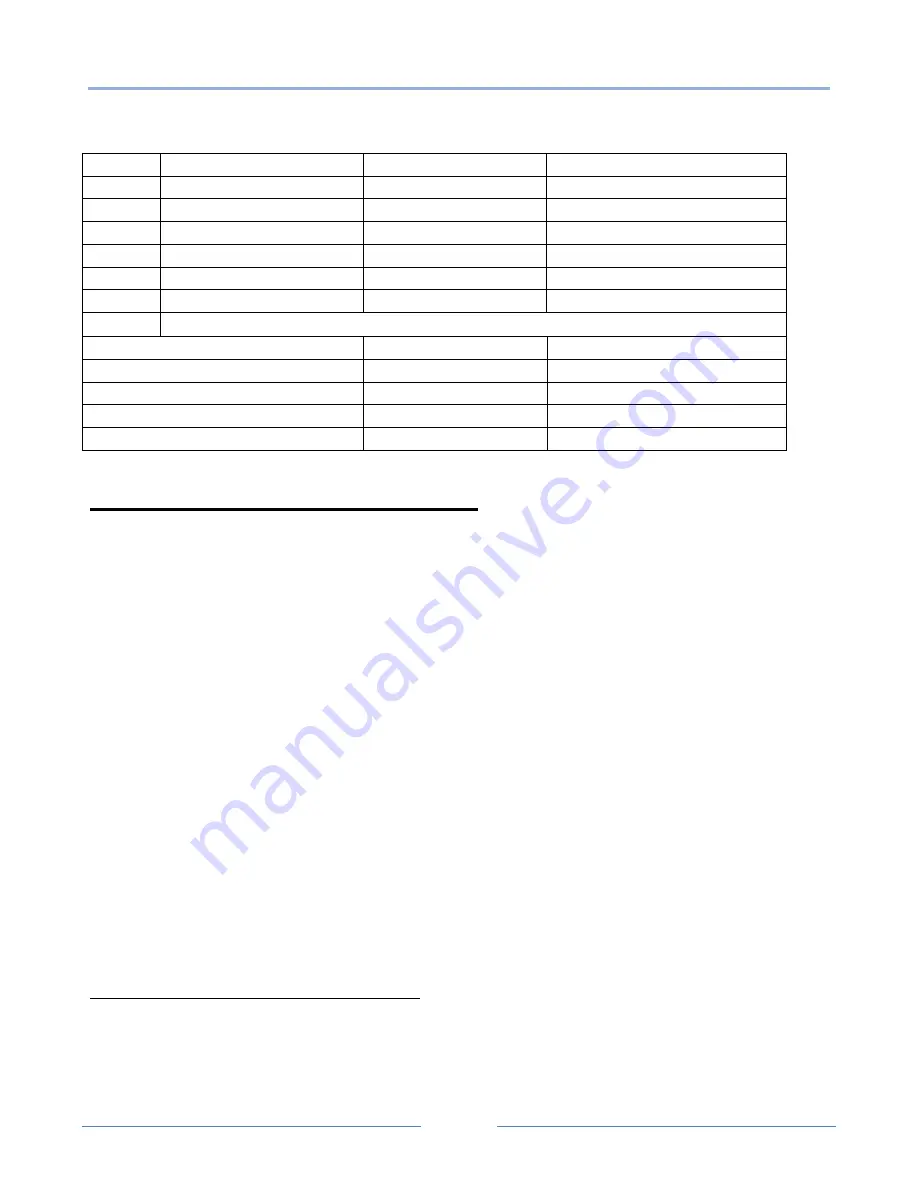

The function of DIP switch setting as follows

:

Switch

Function

(on)

(off)

1

Cutter

No cutter

With cutter

2

Buzzing prompt

Open buzzing prompt

Close buzzing prompt

3

Printing density

High density

Regular density

4

24 bytes mode

No Chinese Character

With Chinese Character

5

Character per line

42

48

6

Select cash box

Open cash box

Close cash box

7-8

Transmission rate (apply for serial interface) (refer to below information)

Transmission rate (bps) -bytes/s

SW-7

SW-8

38400

ON

ON

115200

OFF

ON

9600

ON

OFF

19200

OFF

OFF

Chapter 2. Printer Management

Self-Checking Function

The Self-Checking Function allows the user to identify if the printer is operating normally. If the

printer is detected with failure condition, please contact the distributor.

Self-Checking Process:

Self-checking Procedure

:

1.

Make sure the printer is powered off

2.

Press FEED button and switch on the power supply while the FEED button still pressed.

3.

The Self-Checking list should be printing the printer is brought to power.

Self-Checking function printers out bytes, part of Chinese character set, command mode, interface type,

local printer dial-up switch setting printer setting,…, etc, sequentially.

For the printer equip with auto-cutter, the auto-cutter spontaneously cuts the receipt paper immediately

after finish printing.

The printer automatically goes into data receipt mode after finish self-checking process.

Printer Maintenance

Maintaining the printer regularly is a necessary step to sustain the printer quality as the residual paper wool

got collected through the thermal slice.

Maintaining the Printer with the following steps:

1.

Open the paper roll cover and remove the receipt paper roll if necessary.

2.

Use the alcohol swab to clean the thermal slice printer head

3.

Slight damp a swab and gentle wipe through the roller and the paper checking sensor

4.

Reload the paper roll into the printer and closed the paper roll cover.