T

eMPeraTUre

C

alibraTion

P

roCedUre

C

onT

’

d

as the measured temperature of the top plate. Changes are not saved until

the “SEt” option is selected (and the Last Temperature button is pressed and

released), if the temperature is adjusted too high, delete the SPC adjustment

and repeat procedure.

g. Select the “dn” option if your externally measured temperature of the top plate

is

lower

than the set point on the display. When the “dn” option is selected

the current SPC adjusted temperature will be displayed and blinking quickly.

To decrease the SPC, press and release the Last Temperature button

multiple times (do not touch the heat knob)

until the display reads the value

you recorded as the measured temperature of the top plate. Changes are not

saved until the “SEt” option is selected (and the Last Temperature button is

pressed and released), if the temperature is adjusted too low, delete the SPC

adjustment and repeat procedure.

h. Selecting the “dEL” option will delete

all

Single Point Calibration points and

allow you to exit this SPC mode (see Section c). When the “dEL” option is

selected “dEL” will be displayed. To delete

all

SPC points and exit the SPC

mode release the Last Temperature button when “dEL” is on the display.

i. For set point temperatures with a SPC adjustment, there will be a decimal point

in the display. Once the SPC adjustment is set, the display will blink while the

unit’s temperature is settling. When the SPC set point is reached, the display

will stop blinking and the unit will beep five times.

j. This process may be repeated for up to

three separate

set points. If a fourth

SPC set point is entered, the first set point will be overwritten. To readjust an

existing SPC set point, you must delete the current settings (all SPC points

will be deleted, and the decimal points will no longer be displayed at those

temperatures) and repeat the SPC procedure. If SPC adjustments are

not

deleted

prior to resetting SPC for a set point then the temperature adjustment

will not be accurate

k. The SPC adjustments are limited to the maximum and minimum temperatures

and limits allowed by the particular unit.

10

s

Tirring

o

PeraTing

i

nsTrUCTions

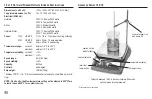

The micro-processor controlled ramping feature slowly increases speed until the set-

point is reached. This feature helps to avoid splashing, improves magnetic coupling and

provides excellent low end control. The micro-processor also monitors and regulates the

stirring speed, sensing your requirements whether you’re stirring an aqueous, viscous or

semi-solid solution.

Initial stirring speed may exceed set speed if the following conditions exist:

1. The stirrer is set at a low speed and the stirrer has not been operated for a extended

period of time.

2. The stirrer is set at a low speed and it is the stirrer’s initial use.

1.

Getting ready:

a. Turn stir knob to the off position. Plug power cord into a properly grounded outlet.

b. Place a vessel with solution and the appropriate spin bar in the center of the top

plate.

2.

Setting speed:

a. Turn the stir knob clockwise until the pointer reaches the desired speed setting. The

stir indicator light above the stir knob will illuminate to indicate the stirring feature is

in use. The stir indicator light will blink while reaching the set-point. Once the set-point

is reached the light will remain lit.

b. Speed adjustments can be made without interrupting stirring by turning the stir knob

clockwise to increase speed, or counter-clockwise to decrease speed.

c. To stop stirring, turn the stir knob to the off position. Your vessel can then be

removed.

Stir protection for Hotplate-Stirrers:

If stirrer motor stops or fails, the unit will automatically shut down the heater.

The stirrer increases speed at a steady rate until the set-point is reached, if the stir bar is

too large or the liquid is too viscous, the stirrer may not reach its set-point. The set-point

speed needs to be reduced. The magnetic strength of stir bars reduce over time and may

need to be replaced.

Stirring vessels in oil baths:

When heating and stirring a reaction vessel within an oil bath or similar set-up, the stirring

function will stir up to

approximately one (1) inch (2.54cm) from the top plate. The stirring

speed will vary according to liquid viscosity, stir bar length and distance from the top plate.

Adjust one or all of these to achieve the desired stirring speed.