10

Safety and Servicing Information

Midian Encryption Programming and Service Manual

June 2006 © Tait Electronics Limited

Components

Replacing components

Ensure that any replacement components are of the same type and

specifications as the originals. This will prevent the performance and safety

of the encrypted radios from being degraded.

Surface Mount Devices

Important

Surface mount devices (SMDs) require special storage, han-

dling, removal and replacement techniques. This equip-

ment should be serviced only by an approved Tait Dealer or

Customer Service Organisation equipped with the neces-

sary facilities. Repairs attempted with incorrect equipment

or by untrained personnel may result in permanent damage.

If in doubt, contact your nearest Tait Dealer or Customer

Service Organisation.

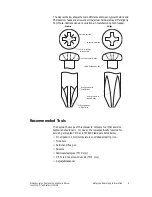

Leaded Components

Whenever you are working on a PCB and removing or fitting components,

you must take care not to damage any copper tracks or pads. The two

satisfactory methods of removing components from plated-through hole

(PTH) PCBs are detailed below.

Desoldering Iron

Method

This method requires the use of a desoldering station.

1.

Place the tip over the lead and, as the solder starts to melt, move the

tip in a circular motion.

2.

Start the suction and continue the movement until three or four

circles have been completed.

3.

Remove the tip while continuing suction to ensure that all solder is

removed from the joint, then stop the suction.

4.

Before

pulling the lead out, ensure it is not stuck to the plating.

5.

If the lead is still not free, resolder the joint and try again.

Note

The desoldering iron does not usually have enough heat to desol-

der leads from the ground plane. Additional heat may be applied

by holding a soldering iron on the tip of the desoldering iron (this

may require some additional help).

Component Cutting

Method

1.

Cut the leads on the component side of the PCB.

2.

Heat the solder joint sufficiently to allow easy removal of the lead

by drawing it out from the component side: do not use undue force.

3.

Fill the hole with solder and then clear with solderwick.