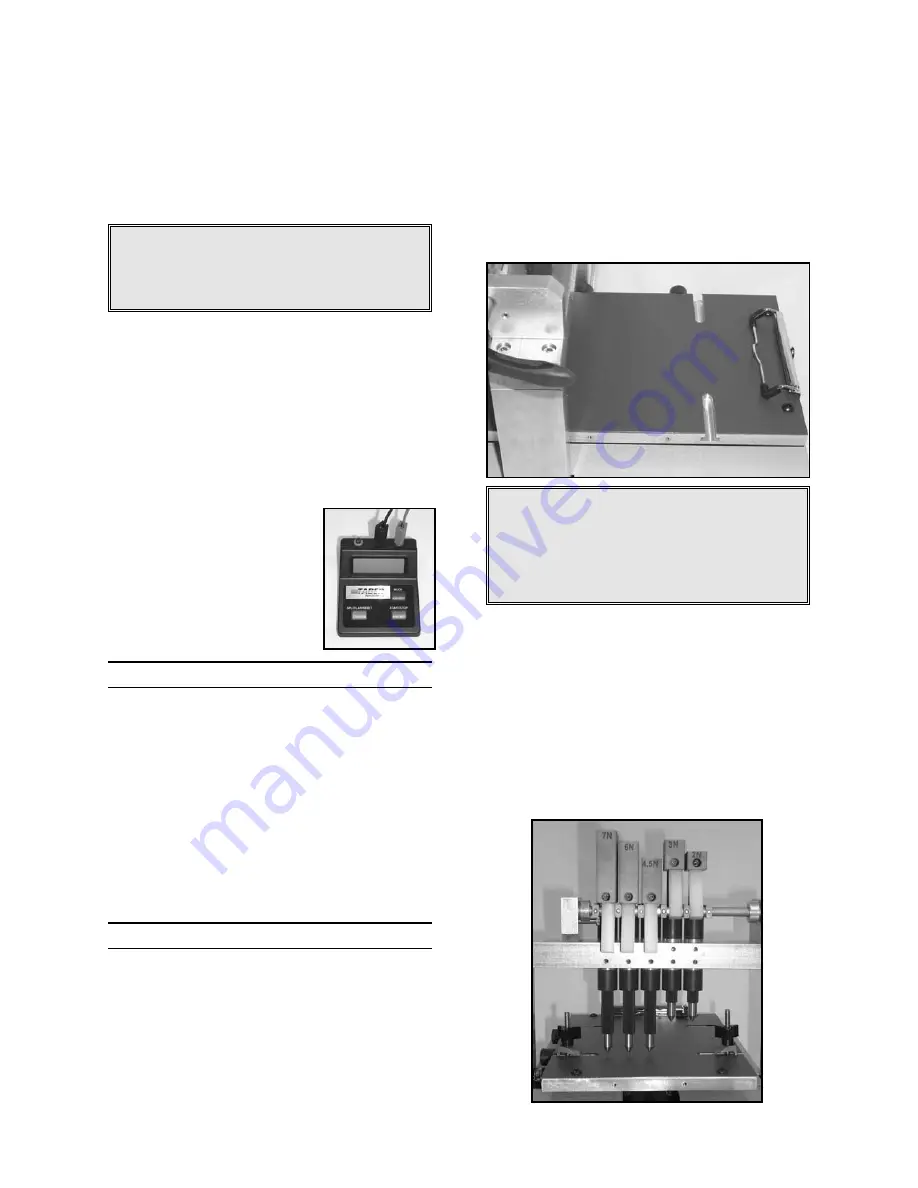

4. Select the weights to be used for testing, and

mount to the top of the spline-shaft finger.

Align so there is not any contact with the adja-

cent weight(s) and tighten in place using the

hex wrench. Weights should be mounted

from lowest to highest load, to permit ease of

evaluation.

X

WARNING: To prevent damage to the

scratch tips, turn the handle to raise the

spline-shaft fingers after the weights are

assembled.

5. Attach the quick disconnect socket (sleeve-

lock, with female ¼" NPT thread) to the air

supply hose, using Teflon tape to seal the

threads. If a local air supply is not available,

it is acceptable to use a compressor that pro-

vides 80 to 100 PSI pressure and has at least

a 2 gallon tank capacity. Fasten the hose to

the Multi-Finger Scratch / Mar Tester air

intake.

6. Connect the electronic

timer, matching the green

and black cables to their

respective sockets (the red

socket is not utilized). Insert

one AA battery, ensuring the

correct polarity.

SPECIMEN SIZE

To provide for an accurate assessment, speci-

mens should be flat panel or regions cut from a

sufficiently flat part. The recommended speci-

men size is 125mm x 300mm, with a thickness

no greater than 22mm. If taken from finished

parts, smaller or slightly contoured samples may

be used.

To test specimens that exceed the 22mm thick-

ness, spacer blocks may be inserted into the

support arms of the gantry.

OPERATING PROCEDURES

Prior to testing, it is recommended that all sam-

ples be preconditioned in a controlled atmos-

phere (such as 23 ±2° C and 50 ±5% relative

humidity) for not less than 24 hours. Samples

should be tested under the same conditions.

Conducting a Test

•

Using the handle, raise the 'fingers' to the

upright position.

•

Place a sample on the platform so the surface

to be tested is facing upward and is located

under the spline-shaft fingers. Taking care

not to deform the specimen, secure it using

the spring clamp or other specimen clamps.

X

WARNING: To prevent movement of the

specimen during testing, ensure the specimen

contacts a 'stop plate'. The spring clamp can

serve this purpose when mounted on the end

of the platform. The stop plate should be locat-

ed on the opposite side of travel.

•

If not already done, install the appropriate

scratch (mar) tips and weights.

•

Using the red button reset the electronic timer.

•

Lower the scratch (mar) tips onto the speci-

men surface and actuate the moveable plat-

form by turning the control knob in the direc-

tion the table will travel. If one or more

scratch fingers are not required, a rest block

is provided to raise the finger out of position.

3

710 Operating Instructions ver 1.1

Summary of Contents for 710

Page 10: ...NOTES ...