INSTRUCTION

MANUAL

22

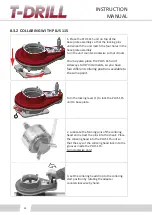

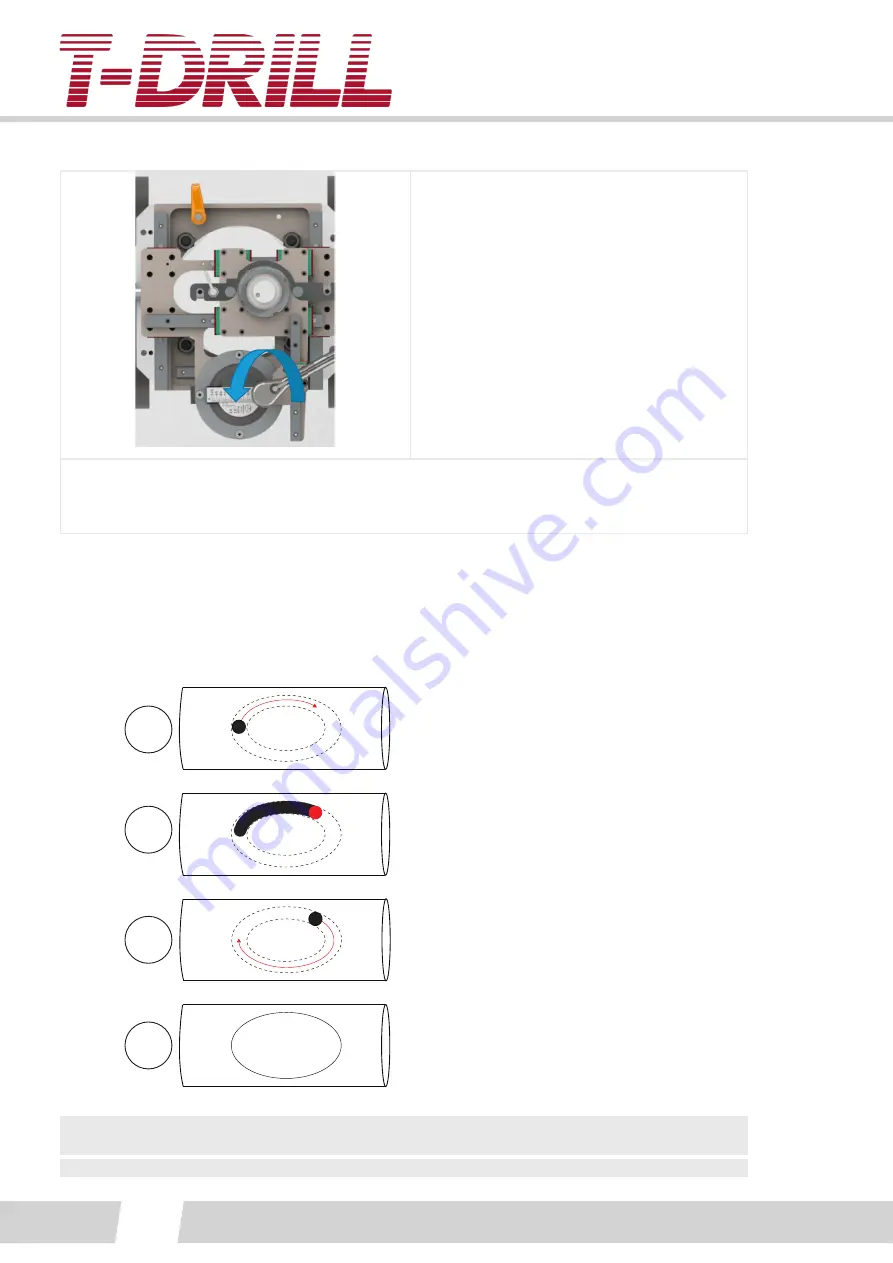

When the drill has passed through the

pipe wall, switch the ratchet reversing

lever and start turning by the ratchet

counterclockwise. Do not use too much

force, but try to keep the milling in motion

without stopping.

Remember to lubricate the milling pin.

When the entire ellipse is milled, lift the

T-65 by the handle and only after the

machine is lifted fully, stop the drill.

Detach the power cord from the T-65 machine.

Remove the T-65 machine from the pilot hole cutter, and remove pilot hole cutter from the

base plate. Clean metal chips from the tube before collaring.

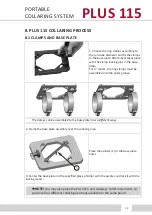

8.2.1 INTERRUPTION OF PILOT HOLE MILLING

If the pilot hole milling process is interrupted, for example, because of pin breakage, do

not restart milling from the starting point, but as close as possible to the point where the

process was interrupted.

Example of interruption and continuing:

1

2

3

4

1. Start milling of the pilot hole.

2. The milling pin breaks.

* Change new milling pin.

3. Continue milling from as close to the

point of breakage as possible.

4. Finished pilot hole.

If the milling is continued from already milled (empty) area, the machine will rush, and

that may cause danger and pilot hole quality deteriorates.

Risk of pin breakage if the milling is started on already milled (empty) area!