Service Instructions

Removing control spindle assembly

(Ref. Parts Assembly figure)

■Shut off water supply to valve

and remove control valve handle

and dome cover.

■Remove escutcheon plate by first

removing escutcheon screws.

■Turn valve’s

control spindle

to half

way position between minimum

and maximum rotation.

Important:

Failure to

do this can damage

control spindle assembly

.

■Unscrew both

spindle cap

and

control spindle assembly.

Hot/Cold Seat Repair Kit

Order p/n TA-4, T-35A and T-35B.

Installation requires both hot & cold

removal tools, p/n

T-35A & T-35B

.

■Remove

control spindle assembly

.

■Remove both seats with removal

tools.

■Replace both seats even if only

one appears worn.

■Install and tighten both seats to

15 foot pounds of torque.

Control Spindle Washer Repair Kit

Order p/n TA-9.

■Remove

control spindle assembly

.

■Remove

cold washer

by holding

spindle using valve handle and

unscrew

cold washer retainer

using channel lock pliers.

■Remove

hot washer

by removing

hot washer screw

.

Checking Water Pressure

Balancing Piston

The perforated end of the

control

spindle assembly

houses the water

pressure balancing piston which is

the heart of the valve.

■Remove

control spindle assembly

.

■Shake spindle assembly and listen

for clicking noise. Piston should

be free to slide back and forth the

full length of its travel.

■If piston appears restricted then

do the following:

(1) Tap the handle or stem end of

the spindle against a solid object

to free the piston.

(2) Try soaking in household

vinegar and repeat step (1).

■If unable to free piston, replace

control spindle

,

p/n

TA-10.

Important:

Do not

attempt removal of

the piston.

Valve re-assembly

Reassemble by reversing above

procedures.

After the

control spindle assembly

(TA-10) is threaded back into the

spindle cap assembly (TA-12A)

ensure

control spindle

is rotated 1/2

turn clockwise from its maximum

counter clockwise rotational

position. Failure to do this will

damage assembly.

Symmons Industries, Inc.

■

31 Brooks Drive

■

Braintree, MA 02184

■

Phone: (800 )796-6667

■

Fax: (800) 961-9621

Copyright © 2017 Symmons Industries, Inc.

■

symmons.com

■

■

ZV-1092R REV A

■

110917

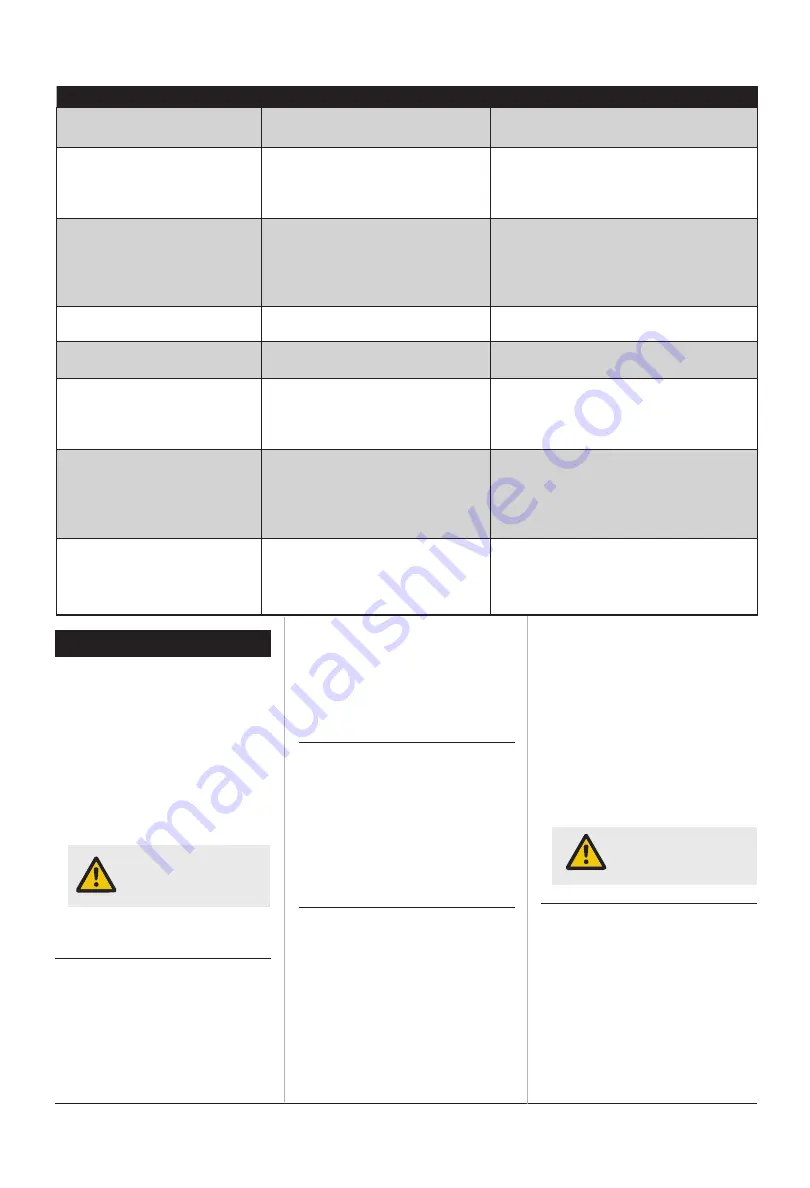

Trouble Shooting Chart

Problem

Cause

Solution

Valve will not pass water.

Both hot and cold water supplies are

not turned on.

Turn on both supplies. Valve will not operate

unless both hot and cold water pressure is on.

Valve leaks when shut off.

Hot and cold washers are worn or

foreign matter (dirt, chips) is lodged

between washers and seat surfaces.

1) Replace washers using

control spindle

washer repair kit

, p/n TA-9.

2) Replace hot & cold seats using

hot/cold

seat repair kit

, p/n TA-4.

Temperature control handle is

turned from cold to hot (or hot

back to cold) and volume from

spout or head is not constant.

Pressure-balancing piston housed in

spindle assembly is restricted from free

movement by foreign matter.

1) Open valve halfway, remove handle and

tap spindle with plastic hammer.

2) Check

water pressure balancing piston

in

control spindle

. See service instructions.

3) Replace

control spindle

, p/n TA-10.

Valve delivers sufficient quantity of

cold, but little hot, or the reverse.

Same as above

Same as above

Temperature varies without

moving handle.

Same as above

Same as above

Valve delivery temperature reduces

gradually during use; handle must

be turned to hotter positions to

maintain constant temperature.

Overdraw on hot water supply

(i.e. running out of hot water).

Reduce maximum flow by using volume

control adjustment on valve or showerhead.

This will allow longer period of use before

overdrawing hot water supply.

Valve delivers hot water when

initially opened. Water turns

colder as handle is rotated in

a counter-clockwise direction

toward the hot position.

Valve is piped incorrectly (i.e. the hot

supply is piped to the valve’s cold inlet

and the cold supply is piped to the hot

inlet.)

If piping is accessible, correct connections to

the valve. If piping is not accessible, order

a

reverse seat and tool kit

, p/n T-108. Older

installations may also require replacing the

hot seat,

hot/cold seat repair kit,

p/n TA-4.

.