GB.COOLDXS.INS.100507

www.swegon.com

13

We reserve the right to alter specifi cations.

!

Warning

Before covers are opened, see section 2, Safety instruc-

tions.

7 Maintenance

7.1 Cleaning

Inspect the cooling unit twice a year and clean if neces-

sary. You should inspect it more often if it operates in a

polluted environment.

It may be suffi cient to carefully brush the condenser coils

clean working from the outside, if there is lighter pollu-

tion.

The cover panel on the cooling unit’s rear can be disman-

tled by loosening screws, if there is worse pollution. Lift

away the cover panel. The inspection covers of the unit

can be opened by unscrewing the knobs in at the bottom

edge of the cover. Take hold of the cover in the handle

and pull the cover carefully outwards. N.B.! Have a good

grip of the cover so that it will not fall down!

If needed, clean the inside cleaning of the unit by vacuum

cleaning and wiping surfaces with a damp cloth.

Condenser coils/air cooler can be cleaned as follows:

Clean the condenser coils only by carefully blowing with

compressed air, vacuum cleaning with a soft nozzle or wet

cleaning with water and/or solvent.

If cleaning solvent is used, do not use solvent that will

corrode aluminium or copper. Swegon’s cleaning agent

is recommended. This cleaning agent is sold by Swegon

Service.

Check in connection with cleaning that the drain pipe of

the air cooler is not clogged.

7.2 Handling of refrigerant

The refrigerant used is R 410A.

The refrigerant circuit is completely charged when the unit

is delivered. No further fi lling is necessary under normal

conditions.

!

Warning

Under no circumstances may the refrigerant circuit be

opened by unauthorised personnel, since it contains gas

under high pressure. Only an accredited refrigeration

company shall be permitted to modify or repair the

refrigeration circuit.

The cooling unit is equipped with a safety valve to

prevent excessively high pressure in the system if the

temperature is high.

Important

Contact Swegon Service in the event of leakage of

refrigerant.

!

Warning

If refrigerant is exposed to fi re or in some other way

becomes superheated in the atmosphere, poisonous

gases can form.

Important

Filling of refrigerant must be performed in accordance

with the recommendations of the refrigerant manufac-

turer.

Direct contact on skin should be avoided with refrige-

rant.

Use tightly sitting protective glasses, protective gloves

and covering work clothes.

In the event of eye contact

rinse the eyes using an eye-wash shower (alternatiing

with lukewarm water) for 20 minutes. Seek a doctor.

In the event of contact with skin

carefully wash with soap and lukewarm water.

In the event of frostbite

seek a doctor.

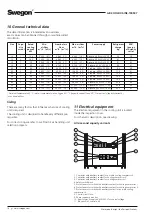

7.3 Periodic inspection

Periodic inspection by an accredited cooling fi rm is re-

quired, if refrigerant volume in the cooling unit is more

than 3 kg. A periodic inspection should be carried out

every sixth month for COOL DXS size 60, capacity variant

1 and 2, and for size 80, capacity variant 2. For other sizes

and capacity variants, a periodic inspection should be car-

ried out every twelfth month.

Obligation to report

You are obligated to fi le a report with the local supervisory

authorities only if the total volume of refrigerant charged

in refrigerating units at a given company exceeds 10 kg.

7.4 Service

Only service personnel trained by Swegon should be per-

mitted to modify the cooling unit.