GB.COOLDXS.INS.100507

www.swegon.com

5

We reserve the right to alter specifi cations.

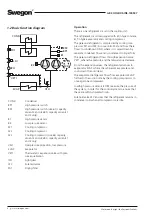

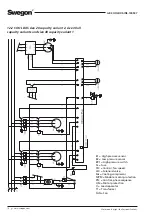

1.3 Regulation

1.3.1 Cooling compressors

The cooling compressors are controlled from the GOLD

unit via relays on the IQnomic Plus module mounted in the

cooling unit.

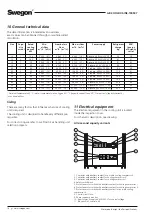

Size 12, capacity variant 1 to size 30, capacity variant 1

These sizes have two cooling compressors of the same

size and are regulated in two steps. The cooling capacity

is regulated 60-100% (equivalent airfl ows, temperatures,

etc.).

Step 1: Cooling compressor 1 starts if there is a cooling

load (the cooling compressor with the shortest operation

time starts fi rst and is called here cooling compressor 1).

Step 2: Cooling compressor 2 starts if further cooling is

necessary and runs at the same time as cooling compres-

sor 1. An adjustable time delay (a stepping duration of

300 seconds) ensures that cooling compressor 2 does not

start until cooling compressor 1 operates at full capacity.

There is a time delay with subsequent down-step switch-

ing if the cooling load decreases. Cooling compressor 2

must have been in operation for at least 90 seconds be-

fore it can be stopped. The restarting time (300 seconds)

for cooling compressor 1 shall have expired to enable it to

start again in Step 1, after it has operated in Step 2.

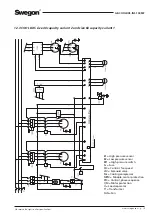

Size 30 capacity variant 2 to size 60 capacity variant 1

These sizes have two cooling compressors of different size

and are regulated in two binary steps. The cooling capac-

ity is regulated 50-75-100% (equivalent airfl ows, tem-

peratures, etc.).

Step 1: When cooling is needed, cooling compressor 1 is

started.

Step 2: If more cooling is needed, cooling compressor 2

starts and at the same time cooling compressor 1 stops.

An adjustable time delay (a step duration of 300 seconds)

ensures that cooling compressor 2 will not start until cool-

ing compressor 1 is operating at full capacity.

Step 3: Cooling compressor 1 is restarted if more cooling

is necessary and is operated at the same time as cool-

ing compressor 2. This third cooling step is also delayed

by the preset time delay setting. Besides this, the restart

time (300 seconds) for cooling compressor 1 must have

expired.

There is a time delay with subsequent down-step switch-

ing if the cooling load decreases. Cooling compressor 2

must have been in operation for at least 90 seconds be-

fore it can be stopped. The restarting time (300 seconds)

for cooling compressor 1 shall have expired to enable it to

start again in Step 1, after it has been operated in Step 3.

Size 60 capacity variant 2 to size 80 capacity variant 2

These sizes have three cooling compressors of the same

size and are regulated in three steps. The cooling capacity

is regulated 50-75-100% (equivalent airfl ows, tempera-

tures, etc.).

Step 1: Cooling compressor 1 starts if there is a cooling

load (the cooling compressor with the shortest operating

time starts fi rst and is here called cooling compressor 1).

Step 2: Cooling compressor 2 starts if more cooling is nec-

essary and runs at the same time as cooling compressor 1.

Adjustable time delay (stepping duration of 300 seconds)

ensures that cooling compressor 2 does not start until

cooling compressor 1 is operating at full capacity.

Step 3: Cooling compressor 3 starts if more cooling is nec-

essary and runs at the same time as cooling compressors

1 and 2. An adjustable time delay (step time 300 seconds)

ensures that cooling compressor 3 does not start until

cooling compressors 1 and 2 are operating at full capacity.

There is a time delay with subsequent down-step switch-

ing if the cooling load decreases. Cooling compressors 2

and 3 must have been in operation for at least 90 seconds

before they can be stopped. The restarting time (300

seconds) for cooling compressor 1 and 2 shall have expired

to enable them to start again in step 1 or step 2, after they

have been operated in Step 3.

All sizes

If any cooling compressor stops, the restarting time must

expire before a restart can take place. The restart time is

calculated from one start to the next start.

If the pressure in cooling circuit becomes too low or if the

pressure in condenser circuit becomes too high, the cool-

ing capacity is decreased by stopping the compressors in

steps until the pressure is stabilised. The text COOLING

PRESSURE LIMITATION is then alternately displayed in the

hand-held terminal of the air handling unit. When the

restart time has expired, the cooling compressor will try to

restart.

If the pressure decreases or increases further, alarm 160

(COOL DXS low pressure below alarm limit) and 161 re-

spectively (COOL DXS high pressure above alarm limit), trip

and the compressors are stopped.

For reasons of safety, there is also a high pressure switch

BP1/2 which interlocks the start signal to the compressors.

Pressure switch BP1/2 can be manually reset by pressing

a button under each protective sock on the upper side of

the pressure switch. This can be done without removing

the protective sock.

1.3.2 Condenser fans

The speed of the condenser fan(s) increase(s) steplessly

to limit the pressure level when the high pressure in the

refrigerant circuit exceeds the limit value.