29

W9

Smart

All rights to changes reserved.

2021-09-23

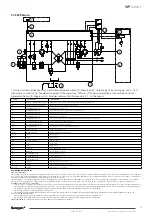

1: Group electrical distribution box | 2: Electrical equipment cubicle | 3: Exhaust air | 4: Outdoor air | 5: Power supply: 230 V, 16 A

with plug-in connection | 6: The damming height of the water trap, 100 mm | 7: Supply demarcation of the ventilation unit | 8:

General ventilation | 9: Supply air | 10: Modular cables with RJ9-connectors | 11: Control panel

7.7.2 W9 Econo

1

2

3

5

6

7

8

9

10

11

4

DESCRIPTION OF FUNCTIONS

CONTROL FUNCTIONS:

The ventilation unit can be operated from a separate Smart control panel or a Smart cooker hood, or remotely via the Modbus field bus or by DCC control. When the ventilation unit is controlled from

the cooker hood in the Home/Away/Boost modes and for local extraction, the time can be set to 30, 60 or 120 minutes. The supply air temperature can be set from the control panel or via Modbus. If

necessary, reheating can be disabled by turning the thermostat to the zero position.

Summer operation: The outside air bypasses the heat exchanger when the room temperature is higher than its set temperature (e.g. T3) and when the temperature of the outside air (T1) is higher

than 14 °C (factory setting) and is lower than the room temperature setting. The fans run at the set speed or are controlled by the control panel to the defined boost speed for summer mode.

INTERLOCKINGS AND SAFETY FUNCTIONS:

–

Freeze protection for waterborne air heaters The ventilation unit will stop if the temperature of the return water from the air heater drops below a limit value. The outdoor air and extract air ducts

are fitted with shut-off dampers with spring return, whose 24 V control voltage is taken from the circuit-board. Shut-off dampers and damper motors are not included in the equipment delivery.

–

The air heater for preheat is equipped with an automatic thermostat TZA1 and a thermostat TZ02 with manual reset (set value 90 °C).

–

The fans have automatic overtemperature protective devices.

–

The ventilation unit is equipped with an automatic defrost system that prevents the heat exchanger from freezing by enabling the preheater and if necessary by changing the fan speed.

IF THE SAFETY EQUIPMENT TRIPS:

–

If an overheating protection with manual reset trips, locate and correct the fault; then press the reset button inside the ventilation unit.

–

The automatic overheating protections of the fans will reset themselves when the temperature has dropped below the setting value.

REMOTE OPERATION: Study the ventilation unit manual and the list of parameters for Modbus.

SYMBOL

DESIGNATION

EXPLANATION

TC1

MANUAL TEMPERATURE CONTROLS

Manual temperature control for the post heating air heater, factory settings 17 °C

TV1

SELF-DRIVEN THERMOSTAT VALVE

Thermostat valve on the air heater for post heating

T1

TEMPERATURE SENSOR

Temperature sensor, outdoor air

T3

TEMPERATURE SENSOR

Freeze protection for water-heated air heater for post heating

T4

TEMPERATURE SENSOR

Temperature sensor, supply air.

T5

TEMPERATURE SENSOR

Temperature sensor, exhaust air

T6–T9

TEMPERATURE SENSOR

Connected to SET, the functions are determined through the programming of SET (accessory)

TZ02

OVERHEATING PROTECTION

Overheating protection with manual reset

TZA2

OVERHEATING PROTECTION

Automatic over temperature protection

SET

CONNECTION UNIT

Connection unit for Smart control signals (accessory)

SEC

EXPANSION CABLE

IO expansion cable, accessory

SMBG

MODBUS MODULE

Modbus expansion module, accessory

F1 + F2

FILTER

Supply air filter

F3

FILTER

Extract air filter

HR

HEAT EXCHANGER

Heat exchanger

SF1

FAN

Supply air fan

EF1

FAN

Extract air fan

SD1

DAMPERS

Bypass damper summer time

SD2

DAMPERS

Shut-off dampers, accessory

SK

AIR HEATER/COOLER

Electric air heater, accessory

LP

AIR HEATER/COOLER

Air heater accessory

VP

AIR HEATER/COOLER

Air cooler, accessory

RH + T

SENSOR

Humidity and temperature sensor

RH + CO2

SENSOR

Humidity/carbon dioxide sensor, accessory

RH + VOC

SENSOR

Humidity/VOC sensor, accessory