12

Operating Maintenance Installation CLASSIC

3:3500-2 --> 860004-02

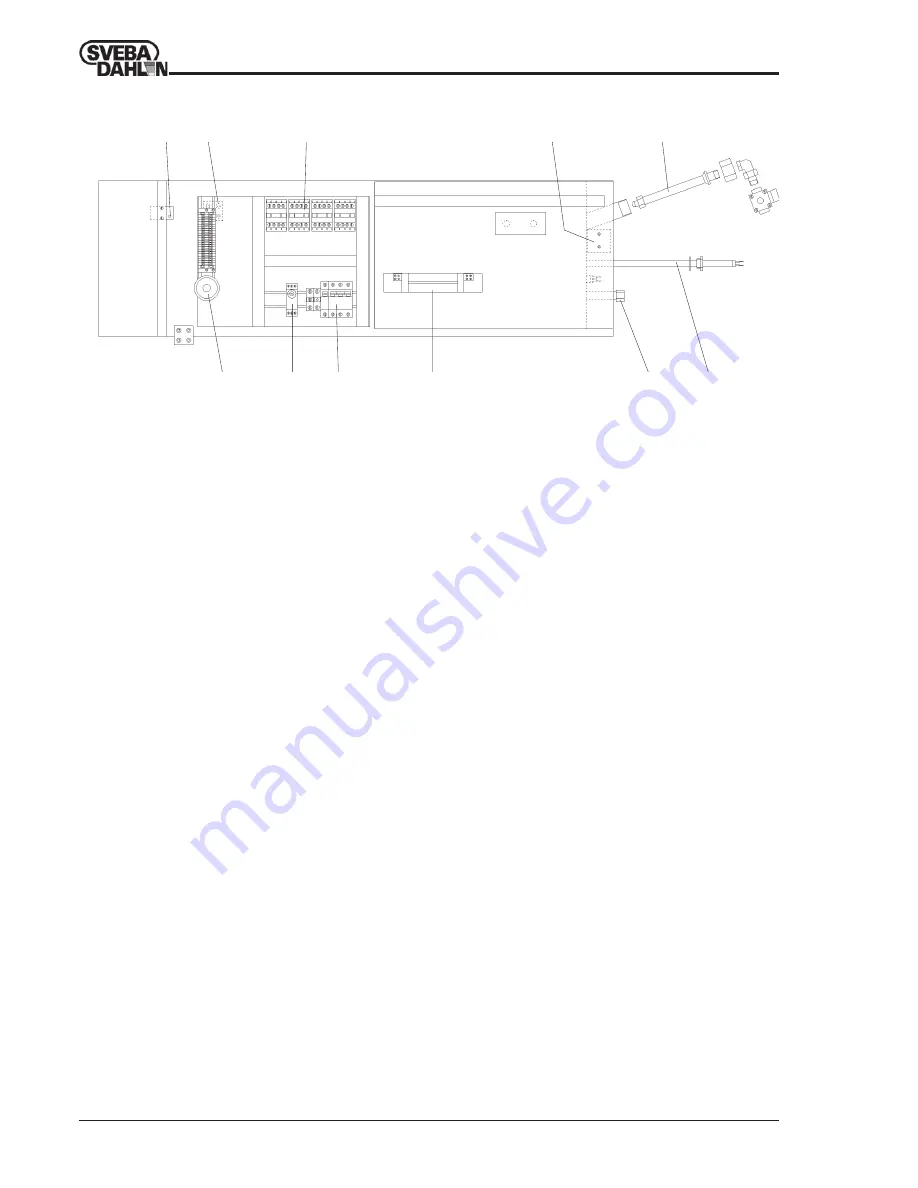

1

2

3

7

8

2

4

5

6

9

10

1 Overheating protection

To get a complete disconnection, the fuse F1 of the

elements will also trip (see point 5 too).

If the overheating protection has triggered this can be

reset by pressing the reset button with a pen. The

button is reached through the small round hole in the

oven right-hand side panel.

Never use electrically conductive object when

resetting! Call technician if the protection triggers

repeatedly.

2 Buzzer

This is connected to the baking timer and gives a

signal when the baking time has expired. At the same

time as the buzzer is activated the green pilot lamp on

the instrument panel lights.

3 Contactor

One contactor for each group of elements, top, bot

tom and front heat. If the oven is fitted with a built-

in steam generator, there is a fourth contactor for this.

4 Time relay 0-100 seconds.

This relay only exists if the oven is fitted with steam

generator. The relay decides how long steam will be

sprayed into the over chamber when the steam control

on the front panel has been turned to the steam

position. The relay is set to 20 seconds on delivery but

can be adjusted where necessary.

Never use longer steam times than necessary since

this will reduce the capacity of the steam genera-

tor.

Fig. 12 Distribution box

DISTRIBUTION BOX

5 Automatic fuse

The 3-pole fuse protects the oven elements. On the

lower section there is also a 1-pole fuse. This is the

oven control fuse and is common to all sections in

the oven.

During service work in the oven the power supply to

the oven must be switched off. It is not sufficient to

switch off the oven built-in automatic fuses.

6 Light transformer

Transformer for the halogen light. Two lamps are

connected to each transformer.

7 Thermostat 300-350°C

Thermostat for regulating the steam generator. The

temperature is locked and cannot be changed.

8 Nozzle pipe

There is a nozzle on the pipe which disperses the

water into the steam generator. In the event of inferior

steam function the pipe can be removed and cleaned.

The nozzle at the end of the pipe is dismantled after

which the strainer and nozzle can easily be cleaned.

9 Drain pipe

This pipe is plugged on delivery. We recommend that

this pipe be connected to a drain by means of a steam

trap. This considerably lengthens the service-life of

the steam generator and its elements.

10 Element

The steam generator has four 500 W elements.