1 5-27

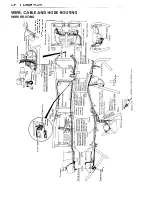

LT-F4WDXM ('91 - M O D E L)

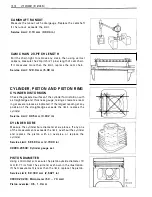

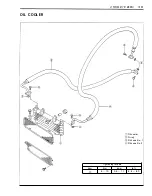

R E M OVAL

•

R e move the fro nt fe n d e r a n d rea r fen d e r .

•

D r a i n e n g i n e o i l .

•

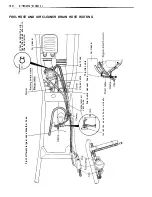

Re move the o i l coo l e r

CD

by remov i n g t h e o i l hose m o u nt

i n g bolts

@

a n d oil c oo l e r m o u nt i n g bolts

@ .

•

Re move t h e o i l h o s e m o u nt i n g bolts

@.

•

Re move the o i l h o s e b y r e m ov i n g t h e o i l hose c l a m p s .

CAUTION :

The removed 0-ring should b e replaced with new ones .

I N S PECT I O N

R o a d d i rt o r trashes stu c k t o t h e f i n s m u st b e removed .

U s e o f c o m p ressed a i r i s rec o m me n d e d for t h i s c l ea n i n g .

F i n s bent d o w n or d e nted c a n be re p a i red by stra i g h te n i n g

t h e m with t h e b l a d e of a s m a l l screwd rive r .

A n y o i l hose fo u n d i n cracked c o n d it i o n o r d a m ag e d m u st b e

r e p l a ced .

I N STA L LAT I O N

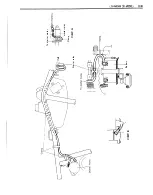

T h i s o i l cooler is t o be i n sta l l ed i n t h e reverse order o f removal ,

a n d refer t o pages 2 6 a n d 4 2 .

•

I nsta l l t h e n e w 0-ri n g s .

•

After i n stal l i ng t h e o i l c o o l e r , be s u re to a d d e n g i n e o i l .

•

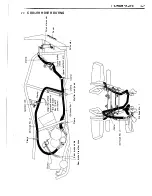

A p p l y S U Z U K I B O N D N o . 1 2 0 7 8 to t h e o i l hose N o . 1

mounti n g bolts

®

and tighte n them to the specified torq u e .

99 1 04-3 1 1 40 : S U Z U K I B o n d N o . 1 20 7 B ( For U . S . A . )

99000-3 1 1 40 : S U Z U K I Bond N o . 1 20 7 8 (For the others)

Tightening torque : 9 - 1 0 N · m

( 0 . 9 - 1 . 0 kg-m, 6 . 5 - 8 . 0 lb-ft )

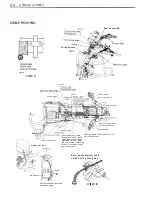

Summary of Contents for LT-4WD 1990

Page 3: ...VI EW O F SUZU KI LT 4WDH 87 MODEL R IGHT SI D E L E FT SI D E ...

Page 5: ......

Page 33: ...2 1 9 P ER I O D I C M A I N T E N AN C E AN D TU N E U P P R O C E DU R ES ...

Page 35: ......

Page 117: ......

Page 119: ...4 1 S H A FT D R I V E A N D D I F F E R E N T I A L D R IVE L I N E ...

Page 177: ...5 1 9 F U E L A N D L U B R I CAT I O N SYST E M LUBRICATION SYSTEM ...

Page 195: ......

Page 197: ...l l C H ASS I S F RONT CAR R I E R A N D F RON T F E N D E R ...

Page 276: ... S E RV I C I N G I N F O R M AT I O N 8 20 000 0 _5 t ...

Page 277: ...8 2 1 S E R V I C I N G I N F O R MATI O N c ...

Page 289: ......

Page 296: ... CONTENTS flf f iJL l flf fl J l f f 1 ...

Page 355: ......

Page 401: ......

Page 433: ...15 31 LT F4WDXM 91 MODEL R EAR BRAKE R EAR WH E E L AN D B ...

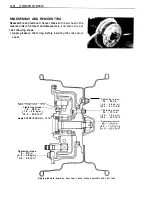

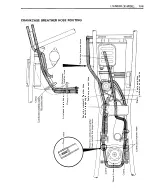

Page 440: ...S t a rter r e l a y V I EW B Battery To starter motor I starter relay C l a m p V I EW A ...

Page 487: ......

Page 505: ......

Page 506: ......

Page 508: ...SUZUKI MOTOR CORPORATION ...