C-8

SC111 Chassis Manual

R90

R89

R88

R87

R86

R85

R84

R83

D8

D7

D6

D5

D12

D15

D14

D13

J1

J4

J3

J2

A

C

A

C

A

C

A

C

A

C

A

C

A

C

A

C

22

21

33

27

8

7

9

22

21

33

27

8

7

9

22

21

33

27

8

7

9

22

21

33

27

8

7

9

FAIL#2

ACT#2

FAIL#3

ACT#3

FAIL#0

ACT#0

FAIL#1

ACT#1

SAS#3

SAS#2

SAS#1

SAS#0

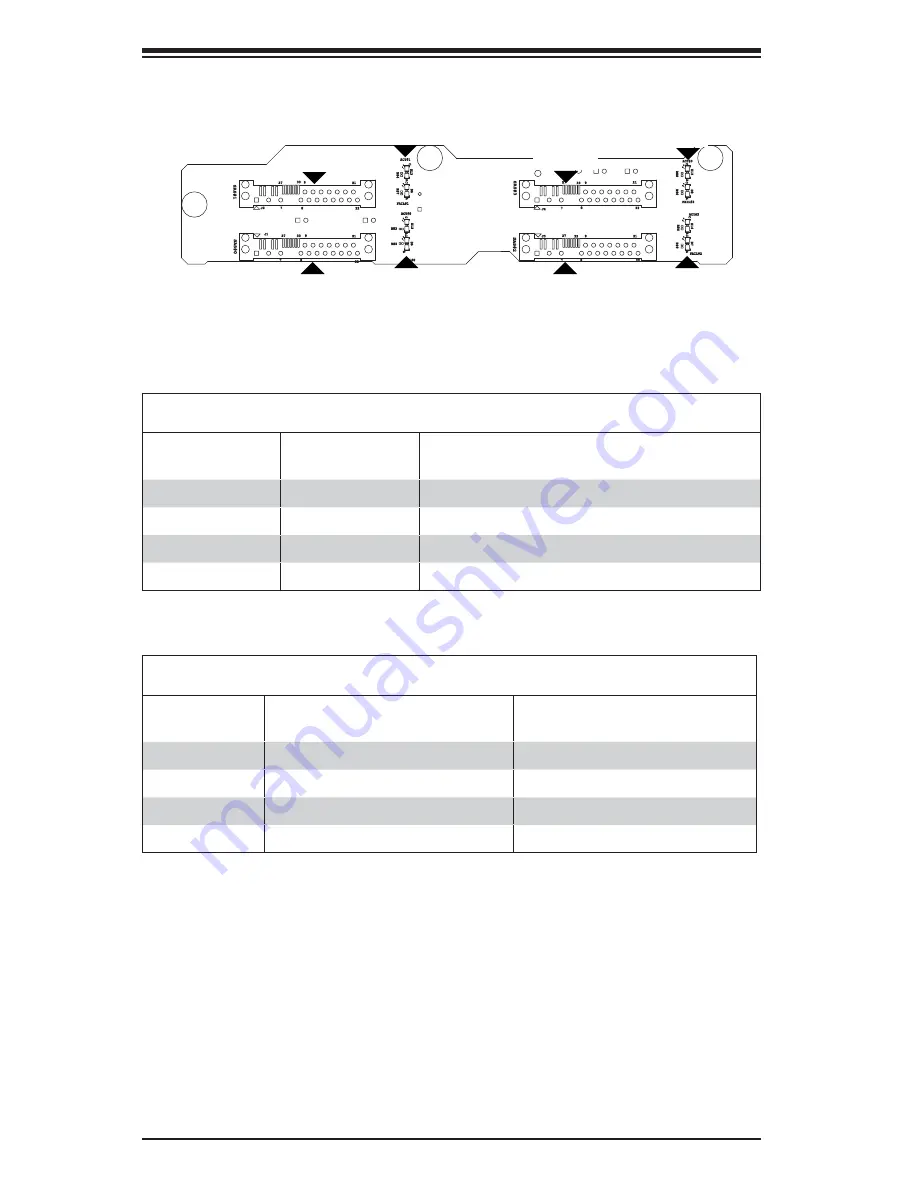

C-7 Rear Connectors and LED Indicators

Rear SAS/SATA Connectors

Rear

Connector

Connector

Number

SAS Drive

Number

SAS #0

J1

SAS/SATA HDD #0

SAS #1

J2

SAS/SATA HDD #1

SAS #2

J3

SAS/SATA HDD #2

SAS #3

J4

SAS/SATA HDD #3

Rear LED Indicators

Rear

Connector

Hard Drive Activity

Failure LED

(Not included on SAS-809T)

SAS #0

D12

D5

SAS #1

D13

D6

SAS #2

D14

D7

SAS #3

D15

D8

D12

D5

SAS #0

D13

D6

SAS #1

SAS #2

SAS #3

D14

D15

D8

D7

Figure C-4: Rear Connectors and LEDs

Summary of Contents for SC111 Series

Page 1: ...SC111 Chassis Series SC111T 560UB SC111T 560CB USER S MANUAL 1 0a SUPER ...

Page 8: ...SC111 Chassis Manual viii Notes ...

Page 24: ...SC111 Chassis Manual 4 6 Notes ...

Page 40: ...SC111 Chassis Manual 5 16 Notes ...

Page 48: ...SC111 Chassis Manual 6 8 Notes ...

Page 52: ...SC113 Chassis Manual A 4 Notes ...

Page 54: ...SC113 Chassis Manual B 2 Notes ...

Page 63: ...C 9 Appendix C SAS 809T TQ Backplane Specifications Notes ...