1-1

Chapter 1: Introduction

Chapter 1

Introduction

1-1 Overview

Supermicro's SC825M(B) 2U 17.7" short-depth design offers advanced air flow

and thermal advantages for front-end servers, database applications, Internet, e-

business, server clustering and other critical server applications. The SC825M(B)

features support for a full range of dual or single processor based E.E. ATX 13.68"

x13" motherboards and flexible interior with three hot-swap hard drive bays. It is

also equipped with redundant 700W or 800W high-efficiency power supplies for

superb power savings.

1-2 Shipping List

Part Numbers

Please visit the following link for the latest shiping lists and part numbers for your par-

ticular chassis model

http://www.supermicro.com/products/chassis/2U/?chs=825M.

Note

: A complete list of safety warnings is provided on the Supermicro website at

http://www.supermicro.com/about/policies/safety_information.cfm

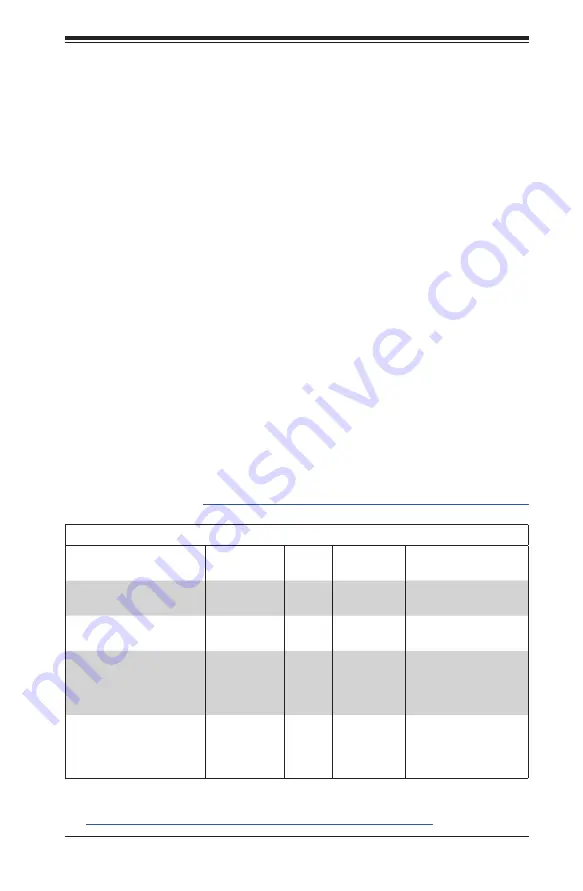

SC825M(B) Chassis

Model

HDD

PCI

Slots

Power

Supply

Description

SC825MTQ-R700LPB

3x SAS/

SATA

7 x LP

700W

Redundant

Standard DVD and

USB/COM port

SC825MTQ-R700UB

3x SAS/

SATA

4x FH

3x LP

700W

Redundant

Standard DVD and

USB/COM port

SC825MBTQC-

R802LPB

3x SAS3

/ SATA

(Front)

7 x LP

800W

Redundant

Optional DVD and

USB/COM port

(Includes dummy

cover)

SC825MBTQC-

R802WB

3x SAS3

/ SATA

(Front)

4x FH

3x LP

800W

Redundant

Optional DVD and

USB/COM port

(Includes dummy

cover)

Summary of Contents for SC825M Series

Page 12: ...SC825M B Chassis Manual 1 4 Notes ...

Page 32: ...2 20 SC825MB Chassis Manual Notes ...

Page 62: ...SC825M B Chassis Manual 5 24 Notes ...

Page 72: ...SC825M B Chassis Manual 6 10 Notes ...

Page 74: ...SC825M B Chassis Manual A 2 Notes ...