SPR-MAN-LM

sprtool.com

PAGE 8 OF 16

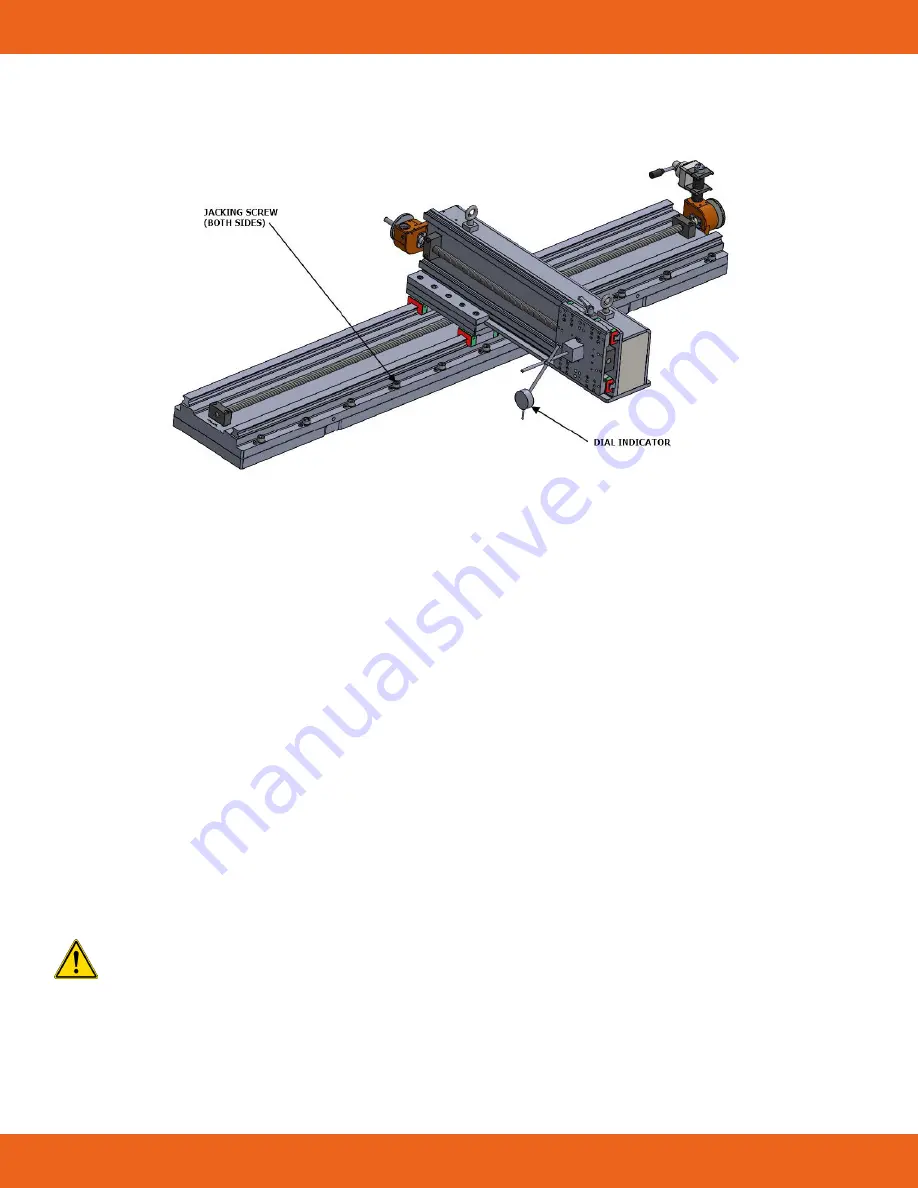

FIGURE 3

7. There are two different methods that can be used to level to mill for machining. One is to use an

indicator as described below, and the other is to use either a machinist level or transit level to level the

rails to the world.

8. Place a DIAL-INDICATOR on the Y-CARRIAGE (Figure 3) and level the machine by adjusting the JACKING

SCREWS while running the DIAL-INDICATOR along both X and Y-axis.

9. Once level, attach the dial indicator next to one set of JACKING SCREWS with the dial indicator

referencing the ground (Figure 4).

10. Carefully tighten the 5/8-11 CAP-SCREWS and the JACKING-SCREWS ensuring that the DIAL-INDICATOR

doesn’t change the position. Repeat for the other sets of JACKING SCREWS.

11. Lightly “Finger Tighten” JACKING-SCREWS into the remaining 8 positions and repeat the tightening

procedure of both JACKING-SCREWS and 5/8-11 CAP-SCREWS using the DIAL-INDICATOR at each new

position (Figure 4) to maintain level position.

Tightening the screws without the DIAL-INDICATOR can cause the X-BASE to bend, reducing flatness

and potentially damaging the machine.