16

3

Adjustment of the Machine

Caution

▶

Always turn off the power when mounting a needle.

If the operator mistakenly steps on the pedal while the power is on, the machine will start

automatically and can result in physical injuries.

▶

When using clutch motor, be aware that the motor will continue to rotate for a while even after

the power is switched off due to inertia.

Start to work on the sewing machine only after the motor has come to a complete stop.

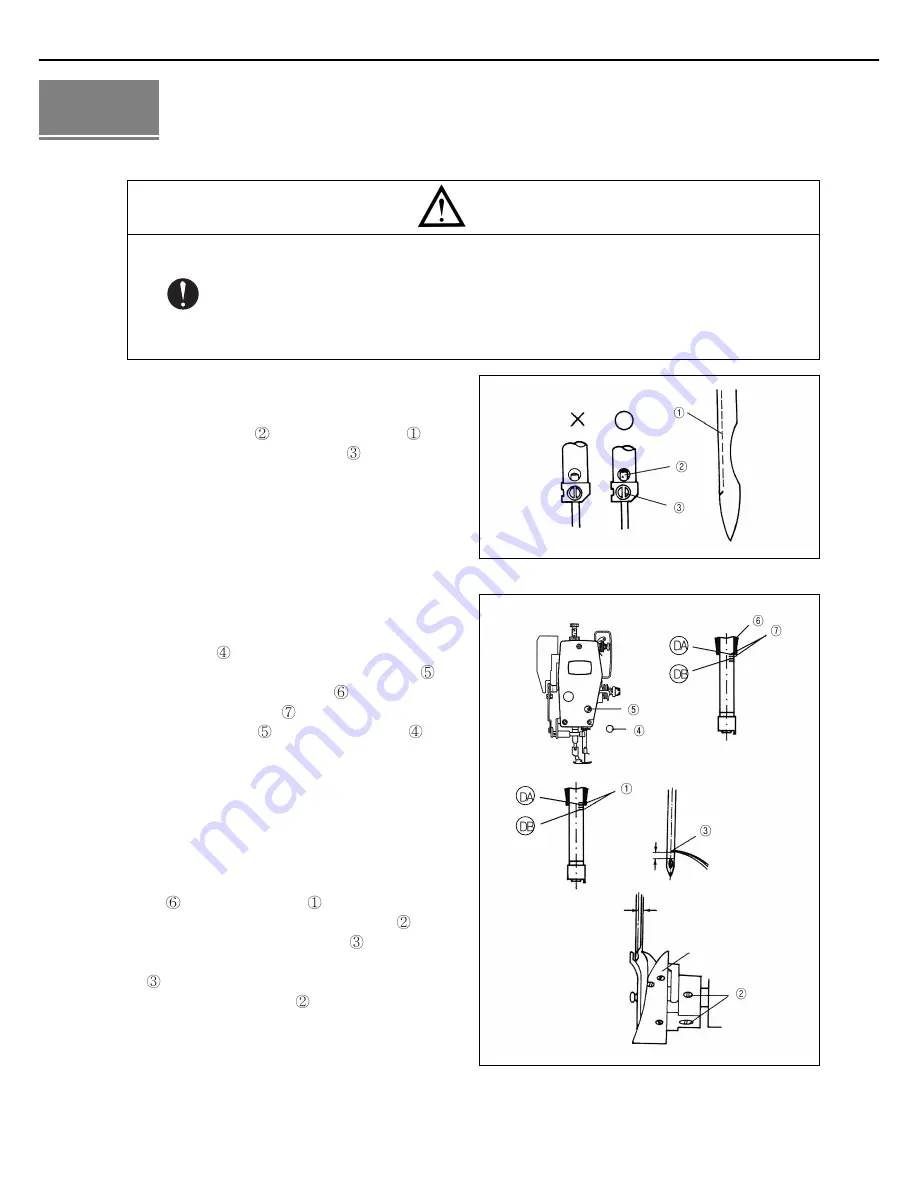

1) Inserting the needle

Place the upper end of the needle closely adhered to the upper

side of the stopper hole , with the needle groove

facing

inward. Fix the needle with a fixing screw . (See Figure 19)

[Figure 19]

[Figure 20]

HOOK

0.05~0.1mm

0.5mm

2) Adjusting needle bar

As can be seen in figure 20, pull out the rubber cover of needle

bar adjusting hole

and turn the pulley to place the bar at the

lowest part. Then, loosen the needle bar clamp screw

and

make the carved sign of the lowest bar

meet the lower part

of needle bar down- bushing

by moving the bar. When is

done, fix the clamp screw

and clog the rubber cover .

3) Adjusting timing of needle and hook

As can be seen in figure 20, make the lower side of needle bar

bushing

meet the carved sign

of hook marked in the

needle bar and then loosen three hook fixing screws .

Turn the loose hook so that the hook edge

meets the needle

center. When this is done, adjust the distance between the hook

edge

and the inner side of the needle groove to 0.05~0.1mm.

Then, tighten three fixing screws

again.