2 Issue 4

28

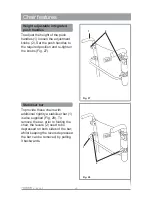

Fig. 35

Chair adjustments

Flip up footrests. Fixed front

frame

To adjust the height of flip up

footrest, remove the bolt (1) as

shown, (use a 10mm A/F spanner)

move the footrest assembly to the

desired position, ensuring the hole

(2) in the outer tube (3) align with

the hole in the inner tube (4).

Replace the bolt and tighten to

5Nm torque setting (Fig. 35).

1

2

Fig. 36

Adjusting the angle of Optima

backrests

To adjust the angle of Optima

backrests (Fig. 36) remove screw (1)

and nut (2) and adjusting washer (3).

Use a 4mm Allen key and a 10mm

A/F spanner. Loosen screw (4)

sufficiently to allow brackets (5-6) to

rotate. Turn the adjusting washer

round to the desired angle and

replace it into the recess (7) with all

the holes in line. Replace the screw

(1) and nut (2) and tighten to 8-10Nm

torque. Tighten screw (4) to 8-10Nm

torque.

1

4

7

3

4

3

5

6

2