SunMaxx Solar LLC

Page 11 of 39

in insulation per the accredited organization. If the auxiliary hot water heater doesn’t

come with insulation, it should be covered with minimum R2.2 insulation with

thickness of 1/4”. (GUIDE: 6.1.1.4)

4.5.1 Different metallic materials

To prevent galvanic corrosion, a dielectric union or coupling should be installed in

between the copper pipe and steel tank.( GUIDE: 6.1.1.10)

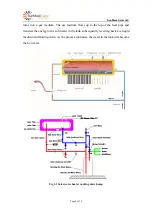

4.5.2 System Tank (GUIDE: 6.1.3.2)

The direct system comes with a 63-gallon tank, no heat exchanger, hence no extra tank

is needed.

4.5.3 Heat Transfer Fluid (HTF) inside the heat pipe (GUIDE: 6.1.3.6 and 6.3.7)

The HTF inside the heat pipe is a small amount of pure water at a very low pressure.

The heat pipe and HTF are built as one unit, no refill is needed, and the water inside

will not be reduced.

No other fluid shall be used that would change the original classification of this system.

Unauthorized alterations to this system could result in hazardous health conditions.

4.5.4 Temperature Sensor Wiring and System Monitoring (GUIDE: 6.1.5.5 and 6.4.1)

Connect either temperature sensor to the cold water pipe and hot water pipe,

respectively. Put one-foot R4.4 insulation on both sensors. The sensor and pipe

intersection point should be in the middle of the one foot insulation.

To determine whether the solar system is working, observe the thermometer when hot

water is being used in the house. The water returning from the collector on a sunny day

should be at least 10°F warmer than the water going up to the collector. The temperature

of the cold water and hot water is displayed on the monitor.

4.5.5 The insulation of the final 5 feet to the auxiliary water heater (GUIDE: 6.1.6.3)

The insulation of the final 5 feet to the auxiliary water heater shall be insulated with R-

0.46 K m

2

/W or greater insulation.

4.5.6 Public Traffic Statement (GUIDE: 6.3.17)

Components exposed to public traffic should be maintained below 140°F or

insulated/isolated to prevent any hazards to public traffic.

4.5.7 Components accessibility (GUIDE: 6.4.6)

All components should be accessible for maintenance and servicing.

4.5.8 Installation and Maintenance Practices (GUIDE: 6.5.5 and 6.5.10)

Do not impair enclosure function. Do not allow vermin intrusion. Ensure applicable

codes and National Roofing Contractors Association practices are followed. The entire

system should be checked by the installer once every two years.

Follow applicable codes and practices when penetrating the structure to install solar

system.

4.5.9 Safe practices (GUIDE: 6.5.11)

Building materials adjacent to solar components shall not be exposed to elevated

temperatures.

4.5.10 System mounting (GUIDE: 6.5.12, 6.5.13, 6.5.14 and 6.5.19)

Allocate a place that is not shaded between 10:00AM and 3:00PM, and keep the solar

panel facing south with 45° of adjustment tolerance. The pitched degree of the panel