8

4

Mechanical Mounting

Respect all local standards and requirements during mechanical installation.

4.1

Location Selection

This section is intended to guide the user in selecting an appropriate installation location.

IIn

nsstta

alllla

attiio

on

n L

Lo

oc

ca

attiio

on

n R

Re

eq

qu

uiirre

em

me

en

nttss

•

With the ingress of protection IP 20, the device can be installed only indoors.

•

Ambient temperature range: -30℃ to +60℃. The relative humidity should not exceed

95%. If otherwise, the internal components will be damaged.

•

The installation environment should be free of inflammable, explosive, and corrosive

materials.

R

Re

eq

qu

uiirre

em

me

en

ntt ffo

orr IIn

nsstta

alllla

attiio

on

n C

Clle

ea

arra

an

nc

ce

e

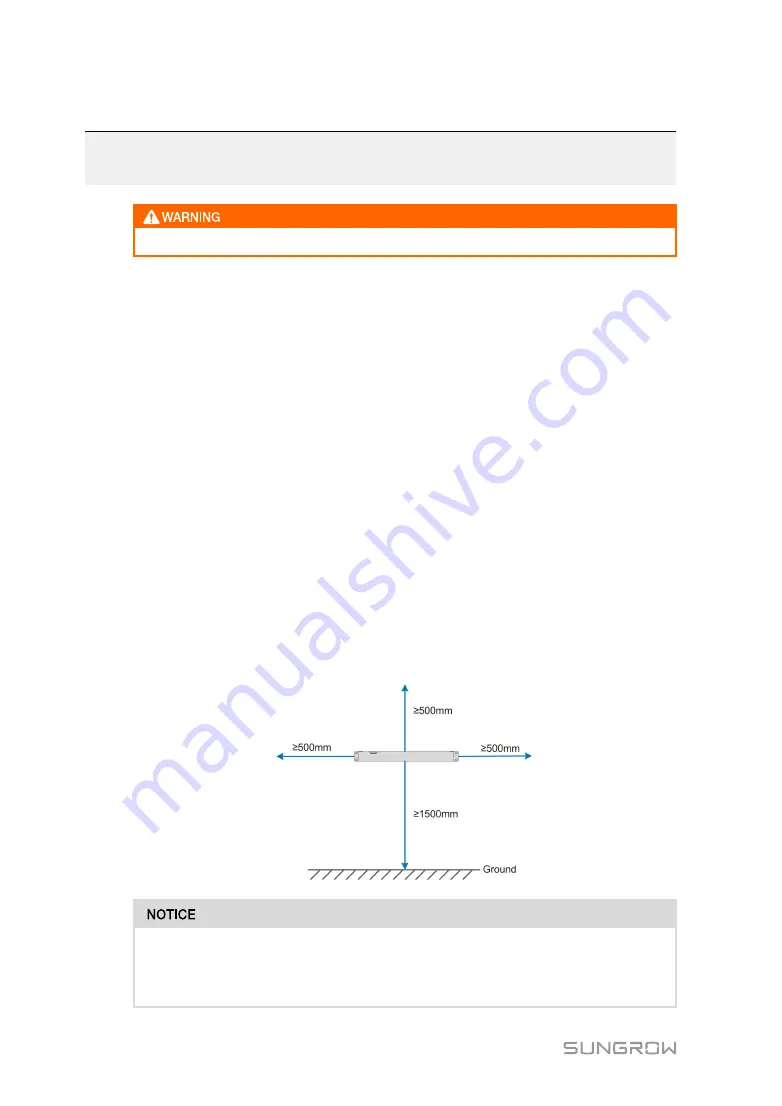

Reserve enough clearances around the device.

Before installation, make sure the wiring terminals are at the bottom of the device to

prevent the dust or particles in the air penetrating into the device, impairing the service

life.

The installation location should be 1,500mm above the ground surface. Clearances of at

least 500mm should be reserved around the device for ease of maintenance. The follow

figure shows the requirement for minimum clearances.

When there are external devices (such as Meteo Station) connected to the

device, users should install corresponding communication SPD according to

onsite conditions.