The following shall be the specifications for the solar collectors. Collectors shall be SunEarth Empire model ________, and shall be of the

glazed liquid flat plate type. Collectors shall be tested in conformance with ASHRAE 93-1986, and SRCC 100-81. The collectors also shall be

certified by the SRCC and the Florida Solar Energy Center (FSEC).

GENERAL

The dimensions of the collector shall be _________ inches in length, _________ inches in width and 3 1/4 inches in depth. The collector cas-

ing shall be an anodized aluminum extrusion (alloy 6063 T5), minimum thickness .060 inch, with an architectural dark bronze finish. The cas-

ing shall have notched framewalls for ease of plate removal and reinstallation. Sheet metal screwed fasteners shall be stainless steel (18-8

#10). The backsheet shall be painted textured aluminum not less than .014 inch thickness. A 1 inch vent plug shall be installed in each of the

four corners of the backsheet to minimize condensation.

GLAZING

The collector glazing shall be one sheet of low iron tempered glass, with a minimum of 1/8 inch thickness (5/32 inch on EP/EC 40), and

a minimum transmissivity of 91 percent (89 on EP/EC 40). The glazing shall be thermally isolated from the casing by a continuous EPDM

gasket. There shall be a continuous secondary silicone seal between the glass and casing capstrip to minimize moisture from entering the

casing.

INSULATION

The insulation shall be foil-faced polyisocyanurate foam sheathing board of a minimum 1 inch thickness, siliconed in place to the aluminum

backsheet, covered by low-binder fiberglass of a minimum 1 inch thickness, providing thermal isolation of the foam from the absorber plate.

Total thermal resistance shall be a minimum of R-12. The sides and ends of the collector shall be insulated with a minimum of 1 inch foil-faced

polyisocyanurate foam sheathing board.

ABSORBER PLATE AND PIPING

The absorber shall consist of a roll-formed copper plate of no less than .008 inch thickness. Risers shall be a minimum of 1/2 inch O.D. Type

M copper tubing on no more than 4 1/2 inch centers continuously soldered to the plate utilizing a non-corrosive solder paste with a melt-

ing point of 460

o

F. The risers shall be brazed to 1 1/8 inch O. D. Type M copper manifolds utilizing a copper phosphorous brazing alloy with

no less than 15 percent silver content, and conforming to the American Welding Society’s BCuP-5 classification. EPDM grommets shall isolate

the manifold from the aluminum casing. The absorber plate shall be designed for 160 psig maximum operating pressure.

ABSORBER COATING AND PERFORMANCE CURVE

A) Black Chrome (EC Series): The absorber coating shall be black chrome on nickel with a minimum absorptivity of 95 percent and a maxi-

mum emissivity of 12 percent. The instantaneous efficiency of the collector shall be a minimum Y-intercept of 0.714 and a slope of no less

than -0.7271 (BTU/ft

2

–hr)/F.

B) Moderately Selective Black Paint (EP Series): The absorber coating shall be a moderately-selective black paint with a minimum absorptivity

of 94 percent and a maximum emissivity of 56 percent. The instantaneous efficiency of the collector shall have a minimum Y-intercept of

0.682 and a slope of no less than -0.7995 (BTU/ft

2

–hr)/F.

Specifications subject to change without notice.

EC/EP20

EC/EP24

EC/EP32

EC/EP40

36 1/8

36 1/8

48 1/8

48 1/8

78 1/4

98 1/4

98 1/4

122 1/4

3 1/4

3 1/4

3 1/4

3 1/4

19.70

24.61

32.79

40.81

17.30

21.88

29.81

37.33

60

80

106

141

73 1/2

93 5/8

93 5/8

115 5/8

0.60

0.78

1.00

1.20

0.51

0.62

0.83

1.04

160

160

160

160

39 3/4

39 3/4

51 3/8

51 3/8

1

1

1

1

W

idth

Inches

Length Inches

D

epth

Inches

G

ross Ar

ea

Sq Ft

N

et Apertur

e

Sq Ft

D

ry

W

eight,

Lbs.

H

eader

, Center

to Center

, Inches

Fluid Capacity

U

.S. G

allons

D

esign Flow

Rate G

PM

M

axim

um

O

perating Pr

ess

PSIG

SunEarth

M

odel N

o.

Std. H

eader

W

idth, Inches

Std. H

eader

D

iam

eter

, Inches

N

om

inal

M

ax Flow

Rate G

PM

12

12

12

12

.015

.017

.018

.020

Pr

essur

e D

ro

p

at D

esign FlowRate

MODEL EP

THERMAL PERFORMANCE RATINGS*

MODEL EC

Inch-Pound Units

Category

(Ti-Ta)

CLEAR

DAY

2000

Btu/ft

2

/Day

MILDLY

CLOUDY DAY

1500

Btu/ft

2

/Day

CLOUDY

DAY

1000

Btu/ft

2

/Day

A(-9

o

F)

B

(9

o

F)

C

(36

o

F)

D

(90

o

F)

E(144

o

F)

1,284

1,169

984

619

280

971

854

677

343

62

659

542

372

89

-

Inch-Pound Units

Category

(Ti-Ta)

CLEAR

DAY

2000

Btu/ft

2

/Day

MILDLY

CLOUDY DAY

1500

Btu/ft

2

/Day

CLOUDY

DAY

1000

Btu/ft

2

/Day

A(-9

o

F)

B

(9

o

F)

C

(36

o

F)

D

(90

o

F)

E(144

o

F)

1,332

1,218

1,040

699

390

1,005

890

720

405

137

680

565

402

127

-

A-Pool Heating (Warm Climate) B-Pool Heating C-Water Heating (Warm Climate) D-Water Heating (Cool Climate) E-Air Conditioning/Industrial Process Heat.

Thermal performance is obtained by multiplying the collector output for the appropriate application and insolation level by the total gross collector area.

*Collector ratings are derived from the Solar Rating & Certification Corp (SRCC) Document RM-1 and Standard OG-100.

Btu

/ft

2

/Day

Ti = inlet fluid temp

Ta = ambient air temp

Btu

/ft

2

/Day

Ti = inlet fluid temp

Ta = ambient air temp

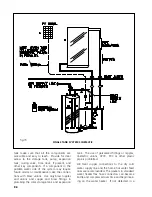

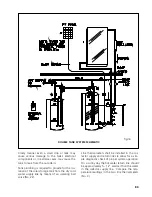

13) EMPIRE COLLECTOR SPECIFICATIONS

P.19