-14-

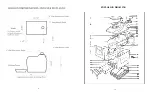

EXCEL AC/DC PART NUMBERS & DESCRIPTIONS

#

PART

DESCRIPTION

# PART

DESCRIPTION

1

EN-0208

TOILET SEAT

26

EN-0173

NYLON DRIVE GEAR

2

EN-0246E

BOWL LINER

27

EN-0194

DRUM SCREEN

3

EN-0249

NYLON DRUM HINGES

28

EN-0104

EXCEL TANK

4

EN-0127

EXCEL DRUM DOOR

29

EN-0571

OVERFLOW DRAIN

5

EN-0107B

EN-0108B

EXCEL COMPOSTING DRUM

30

EN-0310

THERMOSTAT

6

EN-0588

MIXING BAFFLE

31

EN-0120

THERMOSTAT ACCESS PORT

7

EN-0126B

DRUM LOCK MECHANISM

32

EN-0155

HEATER

8

EN-0111B

FRONT BEARING PLATE

33

EN-0187

INSULATION

9

EN-0113

HUMUS DEFLECTOR

34

EN-0197

AIR INTAKE

10

DRUM HANDLE

35

EN-0188

RUBBER “U” CHANEL

11

EN-0198

FOOTREST CHANNEL

36

EN-0106

EXCEL HEATER TRAY

12

DRUM LOCK RELEASE

13

EN-0109

FINISHING DRAWER

14

EN-0122B

FOOTREST

15

EN-0119

FAN COVER

16

EN-0135

FAN CORD

17

EN-0181

POWER CORD

18

EN-0128

FAN DOOR COVER

19

EN-0232

90

O

VENT INTAKE

20

EN-0129

FAN

21

EN-0305

4" NON-ELECTRIC VENT

22

EN-0101

EXCEL TOP

23

EN-0248

FLAT HD. SCREW (#8X

e

” SS)

24

EN-0111B

REAR BEARING PLATE

25

EN-0267

ROLL PIN (5/32 X 1¾” SS)

-7-

INSTALLATION

Inspection

Inspect for

Damage

Remove the "EXCEL AC/DC" carefully from carton. If the product has been damaged,

contact Sun-Mar to determine the best course of action, and :

i) Note the damage description on the shipping papers.

ii) If the shipper has left, report the damage immediately to the transport Company.

Check Carton

Contents

and

Familiarize

yourself with

the Product.

Check that the carton contains both the 2" and 4" vent stacks (pipe, fittings, roof flashings,

insulation, diffusors, a 12 Volt fan for installation in the base of the 4" vent stack), peat

moss mix, and rake.

i) Turn the drum handle clockwise to rotate the Bio-drum for mixing and aeration.

(The drum rotates counter-clockwise and the drum door shuts).

ii) Depress the drum stopper under bowl liner (1993 and prior) or pull the stopper on

the front of the unit (1994 and on) and turn the handle anti-clockwise to simulate

extraction of compost.

(The Bio-drum rotates clockwise and drum door remains open).

iii) If 110 volt power is available, plug the unit’s electrical cord into a standard electrical

outlet, and put your hand at the top rear of the unit to feel the air movement caused

by the fan.

iv) Pull out the compost finishing drawer (situated below the drum) where the compost

drops for finishing.

v) After the unit has been plugged in for five minutes, place your hand on the floor of

the evaporating chamber (underneath where the drawer was) to check it is warm to

the hand, and the heater and thermostat are functioning properly.

Attaching the Footrest

Attaching and

detaching the

footrest

The footrest attaches to the unit into the slot above the drawer by inclining the footrest at

a 45

o

angle to the floor, inserting the round top edge of the footrest profile into the round

top edge of the profile on the unit, and lowering the footrest to the floor. It is detached in

the same way, whenever it is necessary to remove the finishing drawer, by lifting the

footrest until it is at a 45

o

angle and then withdrawing it.

Note:

The footrest is designed as a footrest, it is NOT designed for standing on.

Installing the Toilet

Space Required

When selecting the best place for your toilet, make sure that there is room (an extra 20" is

required) to remove the finishing drawer from time to time.

Other

Considerations

The location of the vent stack, and perhaps the emergency drain may determine the best

place for the toilet. Ensure that the toilet is level front to back or is sloping slightly

backwards. The unit should not tip forward.

Summary of Contents for EXCEL AC/DC

Page 2: ...2 19...

Page 6: ...6 15 EXPLOSION DRAWING...