-4-

HOW YOUR COMPOSTING TOILET WORKS

How Composting Works

Composting is a natural recycling process in

which human waste and toilet paper are broken

down by microbes into their constituent minerals

and converted back to earth. Heat, oxygen,

organic material and moisture are needed to

transform this waste into good fertilizing soil.

Heat is generated by the compost itself, assisted

by a heating element if electricity is connected.

Oxygen is provided by the ventilation system,

and by the tumbling of the composting drum.

Additional organic material is introduced by

adding peat mix (or peat moss).

The waste entering the toilet is approximately

90% water content, which may be evaporated

into water vapor and carried back to the

atmosphere through the venting system. The

remaining waste material is transformed into an

inoffensive earth-like substance.

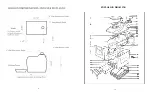

The Sun-Mar "EXCEL AC/DC"

The key to the success of the "EXCEL AC/DC"

lies in it's three chamber design. Each of the

three chambers;- composting, compost finishing,

and evaporation have their own independent

environments for optimum efficiency.

The Composting Chamber

The composting chamber is in the form of a Bio-

drum™ which holds the natural compost heat,

provides the necessary mass to maintain a good

compost, and is rotated by turning the handle to

achieve perfect mixing and aeration.

A drum stopper (beneath the drum handle)

automatically maintains the Bio-drum™ in a

top dead centre position with the drum door

open so that the drum is positioned to receive

new material.

To mix and aerate, the drum handle is rotated

clockwise. This rotates the drum anti-clockwise,

and the drum door closes automatically as the

drum rotates.

Material is extracted by pulling the drum lock,

and rotating the handle anti-clockwise. When this

is done (at a regular speed), the drum door

remains open and some compost falls into the

second chamber;- the compost finishing drawer.

To ensure that the compost remains moist, but

does not get too wet, any excess liquid which the

compost cannot absorb, drains through a screen

at the rear of the drum directly into the

evaporating chamber.

Compost Finishing Drawer

The compost finishing drawer is immediately

below the composting drum, and just above the

evaporating chamber. For seasonally used units,

several drawers of compost are normally removed

at the beginning of the season. Otherwise some

composted material can be extracted into the

drawer and left there for some weeks until it is

time to remove more compost from the drum.

Evaporating Chamber

The third chamber is the floor of the Sun-Mar

"EXCEL AC/DC" which forms the evaporating

pan from where any excess liquids are

evaporated. Air is pulled through intake holes at

the front of each side of the toilet; over the

evaporating chamber, and up the 2" vent stack

(when the unit is operating with 110 volt power)

or up the 4" vent stack when 110 Volt power is

not available. The 2" vent exits from the top

-17-

MECHANICAL TROUBLE SHOOTING (Cont'd

)

Symptoms

Possible

Causes

Remedies

NO

APPARENT

EVAPORATION

110 Volt thermostat

has failed.

The floor of the evaporating chamber is not hand warm.

Replace the thermostat by removing the thermostat

access plate (mid 1993 models and later); or separate

the heater compartment from the unit (mid 1993

models and prior) to access and replace thermostat.

(Detailed instructions are included with the replacement

part.)

110 volt heating

element has failed.

After replacement of the thermostat, if the floor of the

evaporating chamber is still not hand warm;- separate

the 1½" heater base from the unit and replace the

heating element. (Detailed instructions are included

with the replacement part).

Poor Air Flow

See “Poor Air flow remedies”, and ensure drain is

connected.

DRAIN

LEAKING

Drain damaged in

transit or during

installation.

Tip the unit towards the drain until most liquid is

drained out. Wipe drain and wait 1 hour or more for

the drain to dry. Silicone thoroughly around joints

(after roughing up with sandpaper) until the leak or

leaks are sealed.

DRAIN

BLOCKED

Peat moss debris or

ice has blocked drain

fitting, or drain line.

1. Use the rake to extract loose peat moss from

the evaporating chamber.

2. Remove the drawer and clear the block by

pouring ½ bucket of hot water through

drawer opening.

3. If still blocked, force in a 4-6" stick or similar

from the unused side of the drain.

4. If the blockage is in the drain hose;- remove,

flush out, and re-attach.

5. Heat trace drain hose to avoid ice-up

LIQUID

COMING

FROM

DRAWER/AIR

INTAKE

See "Drains Blocked"

causes (above)

See "Drains Blocked" remedies (above), and if not

done, connect drain to avoid re-occurrence.

See “No Apparent

Evaporation” (above)

See “No Apparent Evaporation” remedies (above),

and if not done connect drain to avoid re-occurrence.

MECHANICAL TROUBLE SHOOTING

Summary of Contents for EXCEL AC/DC

Page 2: ...2 19...

Page 6: ...6 15 EXPLOSION DRAWING...