SECTION 2 – SET-UP OF DISK-CHISEL & COULTER-CHISEL WINGS (32’-40’)

2-24

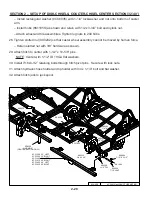

5. Install walking tandem assembly to bottom of liftarm.

– The left hand wing uses a right hand assembly – 8T4168.

– The right hand wing uses a left hand assembly – 8T4166.

– Slide pivot pin (8T3620) through walking tandem assembly and liftarm.

– Insert 7/16 x 3-1/2” bolt in retaining bolt hole. Secure with lock nut.

6. Hang cylinders in appropriate location. Use pins and roll pins.

– Rod end of cylinder must point towards ground.

– Use 6 x 10” (8T1060) on left hand wing.

– Use 4-1/2 x 10” (8T1045) on right hand wing.

7. Install 8K1100 axle and hub assembly into each walking tandem. Apply good quality anti-seize to

axles before installation. Retain axle into receiver tube with 1/2 x 3-3/4” bolt and locknut.

8. Attach wheels onto hubs with 9/16” wheel bolts (torque required: 170 ft-lbs).

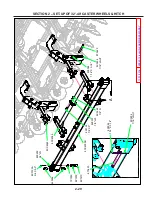

9. 36’ & 40’ – Install wing extensions.

– One-shank extension must be placed on rear rank.

– Two-shank extension must be placed on front two ranks.

– Mounting bolts must point toward outside of machine. (Trip assembly interference will occur

if this is not followed.)

10. Install gauge wheel support (8T4090) onto wing with 7/8 x 2-1/2” bolts.

NOTE: Steps 10 through 15 may have been pre-assembled at factory.

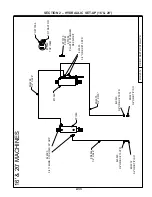

11. Apply anti-seize to jack bolt (8T6000) threads. Screw jack bolt into axle holder (8T4094) far enough

to see hole on bottom of bolt through hole in axle holder.

– Insert 3/16 x 2” roll pin. Insert pin far enough so it will clear tube when rotated.

12. Place gauge wheel depth decal on axle holder.

– Locate decal 1” from bottom of 4 x 4 tube.

– Make sure that decal faces the front of the machine.

– Decal should be placed off to one side of axle holder to avoid seam on support tube.

13. Slide axle holder and jack bolt into gauge wheel support. Slide 1-1/4” flat washer onto bolt and

turn 1-1/4” slotted nut on.

– Do not tighten slotted nut.

14. Add gauge wheel screw top onto jack bolt.

– Insert 1/2 x 2-1/4” bolt into screw top and bolt, secure with locknut.

Summary of Contents for CoulterChisel CC2815

Page 6: ...NOTES iv ...

Page 65: ...2 53 SECTION 2 INSTALLATION OF SHANKS AND COULTER GANGS ...

Page 126: ...6 26 SECTION 6 PARTS ...

Page 128: ...6 28 SECTION 6 PARTS ...

Page 144: ...6 44 SECTION 6 PARTS NOTES ...