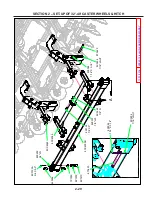

WING & CYL ATTCH

8/13/2012

9DC4012.iam/

16

9"

(32

'-36

')

217

"

(40

')

8T3600

8C6015

8X0234

7/16" LNUT

8X0044

7/16" X 3-1/2"

8CC5050

8X0112

3/4X2-1/4"

8K5515

3/4 X 4 X 6"

8X0306

3/4" LW

8X0260

3/4" N

8X0306

3/4" LW 8X0260

3/4" N

8CC4080

8T4224

LEFT

8CC5052 RIGHT

LEFT

8CC4082 RIGHT

(40' ONLY)

8T4060

8CC4070

(36' ONLY)

LEFT

8CC4072 RIGHT

(36' ONLY)

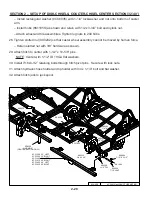

SECTION 2 – SET-UP OF DISK-CHISEL & COULTER-CHISEL WINGS (32’-40’)

2-23

NOTE: It is recommended to set up both sides of machine at the same time. The left hand side is

shown.

1. Attach wing to center section with pins, washers, bolts and locknuts.

– Washers are used to center wing in hinges and prevent shift.

2. Fasten cylinder attach brackets with 3/4” u-bolts, located 169” from machine center.

3. Insert eyebolts (8K1755) into cylinder attach bracket.

– Tighten 1-1/2” nuts so the same amount of threads are above top nut on all eyebolts. Insure

that cylinder attach holes are aligned when eyebolts are tightened.

4. Center liftarm under cylinder attach brackets.

– Use 3/4” u-bolts for 4x4 to attach liftarm pivots (8T4100) to frame.

– The inside pivot will be attached with 3/4 x 6” bolts and a trip assembly.

– Slide pivot pin (8T3640) through liftarm and liftarm pivots.

– Insert 7/16 x 3-1/2” bolt in retaining bolt hole. Secure with lock nut.

Summary of Contents for CoulterChisel CC2815

Page 6: ...NOTES iv ...

Page 65: ...2 53 SECTION 2 INSTALLATION OF SHANKS AND COULTER GANGS ...

Page 126: ...6 26 SECTION 6 PARTS ...

Page 128: ...6 28 SECTION 6 PARTS ...

Page 144: ...6 44 SECTION 6 PARTS NOTES ...