17

640078 ver.01

EN

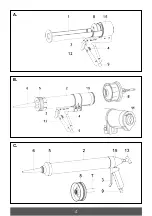

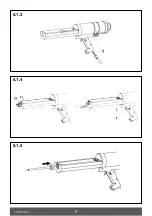

3.3 Functional description

Cartridge:

1-component

and 2-component

coaxial (Category A/D/E/H)

■

■

Connect compressed air (max. 8 bar) to the connection

(9)

(Observe the compressed-air supply requirements (see Chap-

ter «3.4 Technical data»).

■

■

Press the trigger

(3)

to activate the pneumatic piston of the

drive unit (15). The piston

(8)

extends and forces material from

the cartridge.

■

■

The compound being dispensed from the cartridge is fed into

the nozzle. The flow rate can be adjusted by the adjustment

wheel

(4)

.

■

■

When finished, the cartridge can be removed or replaced.

■

■

If replaced, the new cartridge is used to push back the piston

(8)

.

■

■

If a retract button

(10)

is present (Category H) – the piston is

retracted by pressing this.

■

■

Dispose of the used cartridge in accordance with the specifi-

cations supplied by the manufacturer.

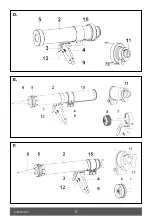

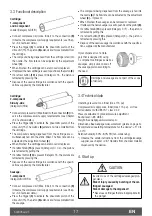

Cartridge:

2-component

Side-by-side

(Category G/H/I/J)

■

■

Connect compressed air (Max. 8 bar) to the connection

(9)

Ob-

serve the compressed-air supply requirements (see Chapter

«3.4 Technical data»).

■

■

Press the trigger

(3)

to activate the pneumatic piston of the

drive unit (15). The pistons

(8)

extend and force material from

the cartridge.

■

■

The compounds being dispensed from the cartridge are si-

multaneously fed into the static Mixer. The flow rate can be

adjusted by the adjustment wheel

(4)

.

■

■

When finished, the cartridge can be removed or replaced.

■

■

If a retract knob

(13)

is present (Category G / I / J) – the pistons

are retracted by pulling this.

■

■

If a retract button

(10)

is present (Category H) – the pistons are

retracted by pressing this.

■

■

Dispose of the used cartridge in accordance with the specifi-

cations supplied by the manufacturer.

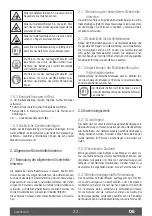

Sausage:

1-component

(Category B/C/E/F/K)

■

■

Connect compressed air (Max. 8 bar) to the connection

(9)

(Observe the compressed-air supply requirements (see Chap-

ter «3.4 Technical data»).

■

■

Press the trigger

(3)

to activate the pneumatic piston of the

drive unit (15). The piston

(8)

extends and forces material from

the sausage.

■

■

The compound being dispensed from the sausage is fed into

the nozzle

(6)

. The flow rate can be adjusted by the adjustment

wheel

(4)

– if present.

■

■

When finished, the sausage can be removed or replaced.

■

■

If replaced, the new sausage is used to push back the piston

(8)

.

■

■

If a retract knob

(13)

is present (Category C / F) – the piston is

retracted by pulling this.

■

■

If a retract button

(10)

is present (Category K) – the piston is

retracted by pressing this.

■

■

Dispose of the used sausage in accordance with the specifica-

tions supplied by the manufacturer.

If your dispenser is of a Cate-

gory that is designed for using

1-component cartridges as well as

sausages, simply click on and off

the sausage-piston according to

the need.

Cartridge and sausage are not part of the scope

of delivery.

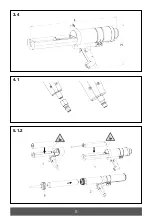

3.4 Technical data

Operating pressure: max. 8 bar (max. 116 psi)

Compressed air supply: max. 8 bar (max. 116 psi) - oil-free

Air requirements: ISO 8573-1 class 2.4.2

Pressure adjustment: gradual pressure adjustment

Sound level: >85 dB (A)

Weight: See webpage www.sulzer.com

Dimensions: See webpage www.sulzer.com (picture on page 6).

Recommended operating temperature for the device*: +5°C to

+ 40°C

Relative humidity: 30% - 80% RH (non-condensing)

*) Observe the safety instructions from the cartridge/sausage

supplier, see chapter «2.8.1 Hazards from chemical material

dispensed by the device».

4. Start up

CAUTION

Incorrect use of the cartridges/sausages/plun-

ger discs.

Risk of injury caused by bursting of the car-

tridges/ sausages!

Risk of damage to the dispenser!

■

■

Never use cartridges that are inappropriate for

the plunger.

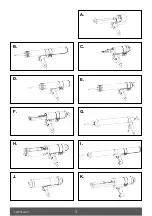

Summary of Contents for Mixpac T1 Series

Page 2: ...2 EN English 11 DE Deutsch 21 FR Français 31 ES Español 41 IT Italiano 51 DA Dansk 61 ...

Page 3: ...3 640078 ver 01 A B C D E F G H I J K ...

Page 4: ...4 A B C ...

Page 5: ...5 640078 ver 01 D E F ...

Page 6: ...6 G H I ...

Page 7: ...7 640078 ver 01 J K ...

Page 8: ...8 3 4 4 1 5 1 2 ...