1.1 g

enerAl

notes

on

sAfety

This operation manual is applicable for the hand tool FH

9-INOX.

The hand tool may only be handled by personnel

who are qualified.

It is imperative that you observe the safety instruc-

tions provided separately for the drive.

1.2 u

se

of

the

mAchine

for

purposes

for

which

it

is

intended

The hand tool ist designed for dry applications on metal

surfaces. They take grinding tools with cylindrical shafts

for polishing and satin finishing workpieces up to 250mm

in diameter. For all other work, e.g. grinding, milling, or

deburring, the max workpiece diameter is 55mm.

1.3 i

ncorrect

use

All uses other than those described under section

1.2 are regarded as incorrect use and are there-

fore not admissible.

1.4 d

eclArAtion

of

incorporAtion

The manufacturer Otto Suhner AG of Industriestrasse 10,

CH-5242 Lupfig, hereby declares for the partly completed

machinery (see reverse side for type and serial no.) that

the following fundamental requirements of the Directive

2006/42/EC are applied and fulfilled in accordance with

Annex I: 1.1.2, 1.1.3, 1.1.5, 1.2.1, 1.2.2, 1.3.7, 1.3.8.1, 1.5.1,

1.5.4, and 1.6.1. Technical documentation was generated

for the partly completed machinery in accordance with

Annex VII of the Machinery Directive. Document Agent:

T. Fischer. Authorised sites are provided with this techni-

cal documentation in paper or electronic form on justi-

fied request. This partly completed machinery may be put

into operation only when the machine in which the partly

completed machinery is to be incorporated has been as-

certained to fulfil the conditions under the Machinery Di-

rective. CH-Lupfig, 10/2019. T. Fischer/Division manager

2. C

ommISSIoNINg

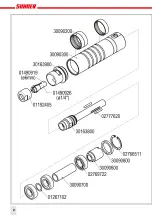

2.1 A

ssembly

instructions

It is imperative that you

read Sections 2 and 3 be-

fore you start operating the

hand tools.

Use only hand tools, shafts, and grinding tools in perfect

condition.

Attach the hand tool to the shaft only when the drive is

switched off and has come to a stop.

1. N

oTES

oN

S

aFETy

Connect grinding tools only when the drive is switched off

and has come to a stop.

It is imperative that you use the guards intended for the

hand tool.

Observe the specifications applying to your country.

2.1.1 A

ttAching

/

detAching

the

hAnd

tool

Press the locking button and insert the hose coupling into

the hand tool hole. Make sure that the locking button is

engaged.

Follow these instructions in reverse order to detach the

hand tool.

2.1.2 A

ttAching

/

detAching

the

grinding

tool

Use a single open ended spanner to hold the spindle in

place at the key face, and loosen the chuck. Insert the

abrasive tool’s clamp shaft to the stop in the chuck. Tight-

en the chuck.

Follow these instructions in reverse order to detach the

grinding tool.

Use only those tools recommended by SUHNER.

You must also observe the safety instructions is-

sued by the manufacturer of the tool.

You must check that the tool’s diameter is within the limits

and the max speed is higher than the tool’s idle or set

speed.

The tool shaft must fit precisely in the receiver.

The tool must be secured as deeply as possible in the

receiver. The larger the exposed shaft length and the

shorter the clamped length, the lower the max speed.

The installed tool must be able to rotate freely. Afterwards

a test run must be conducted without load for at least thir-

ty seconds. Vibrating tools must be replaced immediately.

16

EN