STA 01-380 series 7

!CAUTION ! Cross Threading Components:

Cross-threading components during assembly is not covered under war-

ranty.

Cross-threading is a term that describes damage that is caused when a

misaligned screw or knob thread is forced into a threaded hole. When this

occurs, threads are damaged and are no longer capable of proper opera-

tion. The remedy is replacement or repair of the damaged component/s.

AVOID cross-threading of mounting screws and knobs during assembly us-

ing this easy to follow procedure:

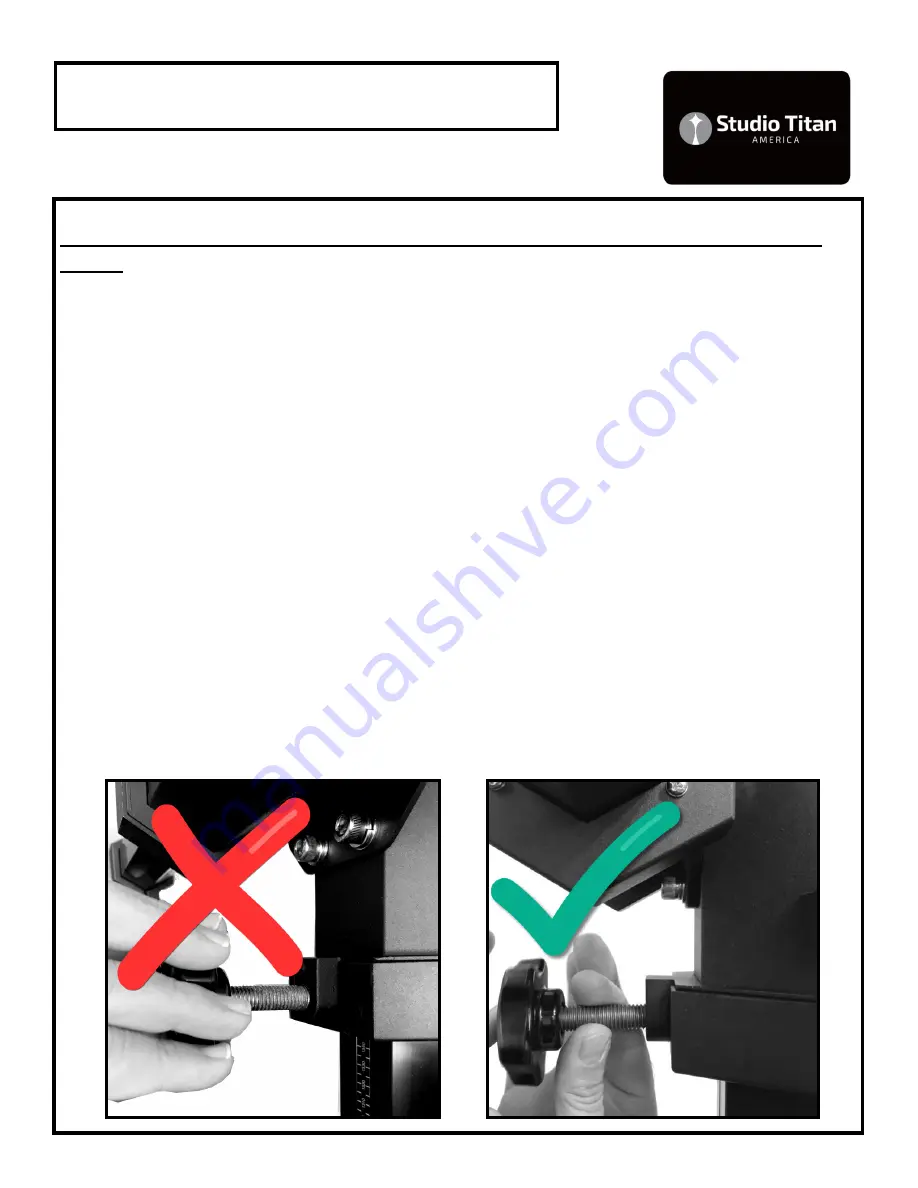

While standing in front of and looking into the threaded hole. Place the

screw or knob thread against the threaded hole. Using one hand, hold the

thread between your fingers. With the other hand hold the hex key like a

pencil or place your index finger in the center of the knob. Align the screw

or knob with the hole as indicated in the picture with the checkmark be-

low. Slowly turn it counter-clockwise or left, several turns, until you hear a

click or feel the start of the thread. Then proceed slowly, turning clockwise

or right, gently using only finger force to tighten the screw or knob. If you

feel increased resistance, the threads are not aligned, remove and start

procedure from the beginning again.