12

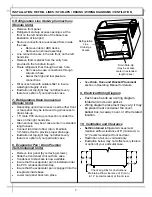

DRAIN, HOSE AND BRACKET PLACEMENT ILLUSTRATIONS

NOTE: BELOW ILLUSTRATIONS MAY

NOT EXACTLY REFLECT EVERY

PARTICULAR CASE’S FEATURES

2. Hot Gas Evaporator System.

•

Hot gas serpentine coil is routed through a condensate

reservoir allowing water to be heated. This system

uses a wicking material (partially submersed) with

warm condenser air passing through it for evaporation.

•

Also incorporates an overflow reservoir with heating

element to ensure complete condensate removal.

Three Evaporator Systems Are Illustrated Below:

Illustration #1: Hot Gas “CopeVap” Evaporator

System. “Copevap” is built into Compressor Unit.

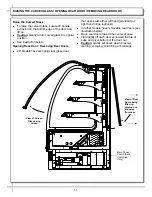

Illustration #2: Hot Gas Evaporator System.

Illustration 3A/3B : Electrical Heat Rod Evaporator

System. Note: Separate Evaporator Pan.

Warning! Regardless of Evaporator, the Hose and

Drain Trap MUST BE secured and positioned over

Evaporator Pan to prevent water seepage / spillage.

When sliding out Condenser Unit, be careful that

drain is not pulled from proper position.

1.

Hot Gas “CopeVap” Evaporator System.

Clear PVC

Tube

Drain Trap

Hose thru bracket

Bracket

Note: Drain

positioned

directly over

Reservoir

“CopeVap”

Reservoir

Clamp

3B. Isometric View of

Electrical Heat Rod Evaporator System

Evaporator Pan

Evap. Pan Positioning Bracket

Use Hose Clamp

to Secure Hose

to Adapter

Clear PVC

Tube

Evap. Pan

Positioning

Bracket

Drain

Trap

Refrigeration

Assembly

Base

Compressor Pan

Shipment Screw

(1 at each side)

Wicking

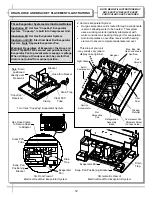

Material

This area of your unit

may widely vary (due to

display case options).

Suction

Accumulator

Hot

Serpentine

Coil

Receiver

Elec. Box, Hot

Gas Condensate

Overflow

Scroll

Compressor

Fan

Shroud

Filter

Drier

Sight Glass

3A. Front View of

Electrical Heat Rod Evaporator System

Evaporator

Pan

Drain

Trap