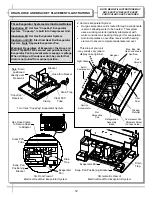

INSTALLATION: FRONT GLASS ALIGNMENT & ADJUSTMENT

10

—- Front Glass —-

Case with Curved

Front Glass

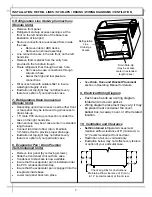

16. Front Glass Alignment & Adjustment via Levelers

•

Proper alignment of the front glass is important to create and maintain a seal inside the case.

•

Improper alignment can cause air leaks compromising the environment inside the case and create condensation.

•

Follow the five steps listed below to assure proper front glass alignment.

2. Front-to-Back Leveling:

•

Place a level on top of case,

perpendicular to front glass.

•

Raise or lower either side of case by

rotating levelers to center the level

bubble (follow steps 3 and 4).

•

Double-check the side-to-side level.

1. Side-to-Side Leveling: Place level on top of display case (parallel

to the front glass). Raise or lower either side of the case by rotating

levelers to center the level bubble (following steps 3 and 4 below).

5. Verification:

•

After adjusting

the levelers,

open and shut

the front glass.

•

Verify again that

front glass is

properly aligned

at both left-hand

and right-hand

side of case.

•

If not, repeat the

above procedure

until front glass is

properly aligned

along both sides

of case.

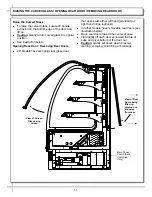

18. Front Glass Alignment & Adjustment

via Clamshell Allen Screw Adjustment

•

Make certain case is level and plumb.

•

Lift glass to maximum upright position.

•

Determine which side requires realignment.

•

While maintaining grip on glass, loosen the Allen

screws nearest to misaligned side.

•

Adjust the glass until properly positioned.

•

Allen screws may now be tightened (taunt, but

not overly tightened lest glass breakage occur).

•

If other side needs alignment, repeat steps while

maintaining grip on glass.

•

Illustrations at right may not exactly reflect every

feature or option of your particular case.

FRONT

GLASS

PANEL

LIFT

END PANEL

4. If FRONT-RIGHT CORNER

is too close to end panel (or

hitting it), adjust levelers at

the BACK RIGHT CORNER

of case DOWNWARD.

LIFT

PANEL

FRONT

GLASS

3. If FRONT-LEFT

CORNER is too close to

end panel (or hitting it),

adjust levelers at the

BACK LEFT CORNER of

case DOWNWARD.

END PANEL

Allen

Screw

Lift Handle

Clamshell

Upper

Clamshell

Lower