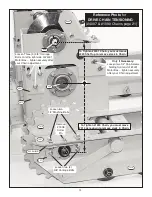

#213 Idler Axles and the two #214 Rear Axles and

are lubricated from the sides of the Crawler (See

Part Drawing MH-B).

The Front Idler Sprocket assemblies have

#1523 grease fittings mounted in their Tubes and

are lubricated from the front of the track on the

inside part of the tube by the yellow spring. The

tracks may have to be rotated to find this 45

degree grease fitting. (See Photo MH-12). It is a

good idea to clean out the track system of debris

each time you lubricate to spot problems before

they become expensive maintenance items.

TRACK IDLER MAINTENANCE

NOTE

: The #1218 Track Idlers are made of a

slightly softer steel than the Track Chain. This has

been done to allow the inevitable wear to be

concentrated on the less expensive Idlers thereby

protecting and greatly extending the life of the

much more expensive Track Chain.

The Track Idlers, after a few hours of running

time, will have their inside walls

hard-peened

into

a configuration that will precisely mate with the

contour of the Track Chain they are guiding. This

peening

process creates not only a mating inside

surface on each Idler, but also rolls a wider

extended

edge

around

each

Idler’s

circumference. In addition, the Idler surfaces are

“work hardened” by being

peened

against the

harder Track Chain.

The #1218 Track idlers are equipped with two

internal oilite bushings. As these bushings wear

the idler will become loose on the axle. These

bushings can be replaced to extend the life of the

idler.

The 4.5” diameter flanges of the #1218 idlers will

continue to wear over time.

Individual idlers

should be replaced when track chains begin

wearing into the tube connecting the flanges.

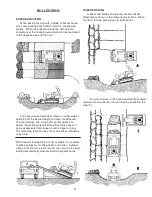

TRACK SHOES

Your Crawler comes from the factory without

any Track Shoes being installed unless you had

the factory install them for a fee. You can safely

run your Crawler without Track Shoes, but under

average soil conditions you will be able to attain

only about 70% of your Crawler’s tractive ability.

To gain more traction, you can add the A-

TSO40 GROUSER SHOE KIT or A-TSO45P

NON-MARKING SHOE KIT. Under average soil

conditions, the addition of Non-Marking Shoes to

your Track will increase traction to approximately

80% of your Crawler’s tractive ability.

Adding

Grouser Shoes will give you the greatest tractive

ability your Crawler can deliver.

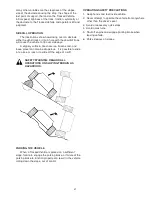

GROUSER SHOE INSTALLATION

Align 3/8” square holes in each Grouser Shoe

with mating 3/8” square holes in

top outside face

of each Track Plate and secure with

3/8x3/4”

Carriage Bolts and 3/8” Flange Lock Nuts.

Using pneumatic tools to do this installation

will greatly speed up the process.

In addition,

securely blocking the tractor on it’s round steel

tubing that goes through the undercarriage is a

good place to block the tractor. Once you have the

tractor up and well blocked, you can run the tracks

around to help with the installation of the shoes. If

you choose not to block the tractor and do the

installation with the tractor firmly on the ground;

you will have to run the tractor forward every

couple of feet to do the installation.

NON-MARKING SHOE INSTALLATION

The method for blocking the tractor is the

same. See the instructions for optional A-TSO45P

Non-Marking Shoes.

28