STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR:

STREBEL CIS

Page 8

V.1-03.08

Important Assembly Advice:

Please read through before starting the assembly!

The boiler is normally delivered in individual sections, which are assembled as a

boiler block by means of tapered nipples.

The watertight joint between two boiler sections is a high-precision press fit

between the boiler nipple and nipple port. The block assembly must be carried

out accordingly with precision.

The following points should be observed during assembly:

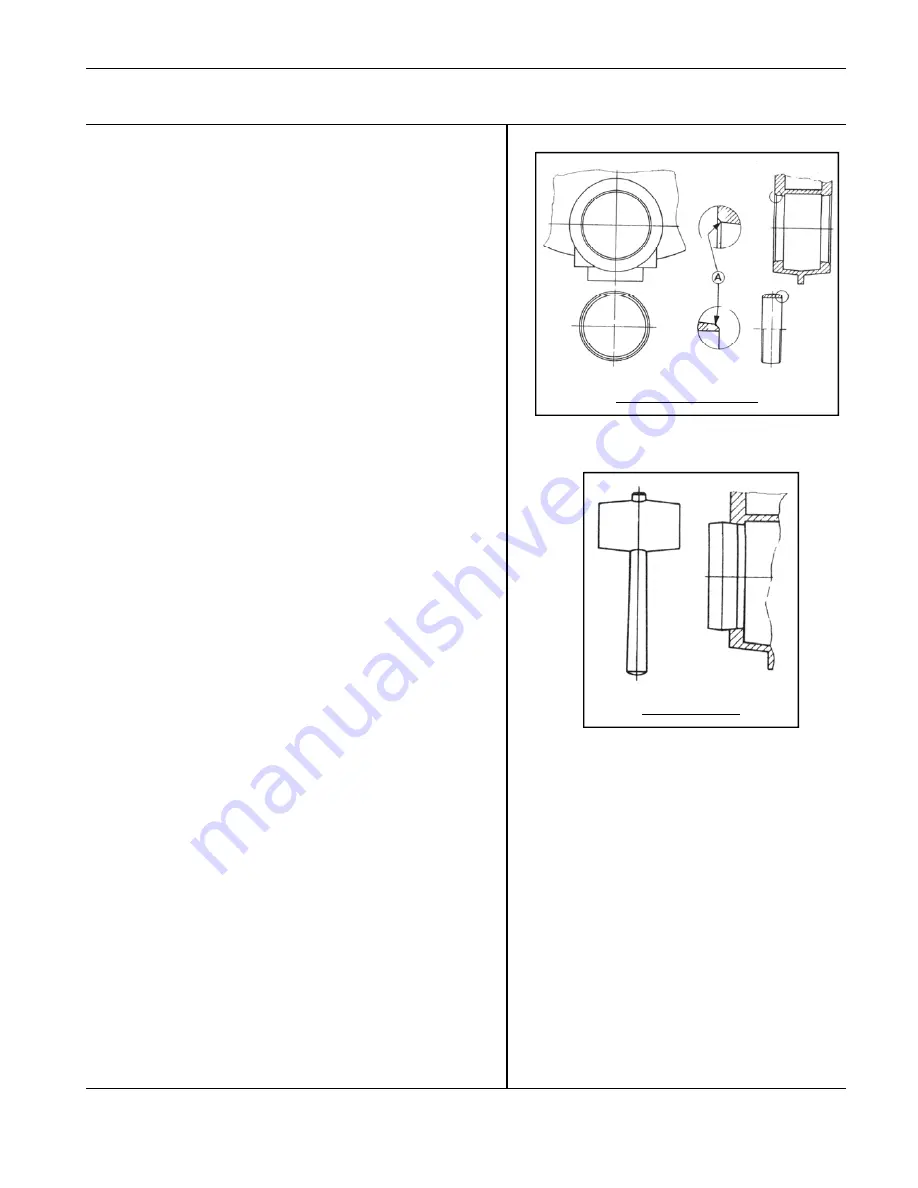

No damage to the nipple and borings should be apparent.

Before a nipple is inserted and a section fitted, the nipple and the boring should

be inspected. Any damage, e.g. to the face of the boring, destroys the nipple seal

and leads to leakage.

Attention!

Minor damage (transport damage) to the faces of the boiler nipple or

to the nipple ports (A) can be corrected with a small smoothing file and emery

cloth without affecting the water tightness of the joint.

→

The accompanying nipple jointing oil sealing compound serves as a lubri

cant as well as a waterproof seal and must be used.

→

During the assembly no dirt should be allowed to remain on the nipples

or in the boring. These should be inspected during each assembly

phase, but particularly before fixing on the pulling–up flanges. Particles of

dirt, which are not removed, can lead to leakage.

→

During the boiler block assembly take care that the various boiler sec-

tions are fitted to the various positions, depending on the model.

→

Boiler nipples and nipple ports must align exactly at all stages of the as-

sembly.

→

An inclined inserted nipple leads to leakage.

A boiler section is built on basically in three stages: In addition, certain specific

points should be observed at each stage:

Stage 1:

Drive nipple into boring with care

Inspect nipple and boring for damage.

Smear linseed oil sealing compound over nipple and boring. Gently drive nipple

into flow and return nipple ports using a mallet or synthetic hammer. The nipples

must remain firm and exactly vertical in the nipple ports and must be able to take

the next boiler section without twisting from nipple port. Take care, inclined

nipples lead to leakage.

Stage 2:

Joining the boiler section to both inserted nipples.

Inspect nipple and nipple port for damage.

Smear linseed oil sealing compound over nipple and nipple port. Cover one

section with boiler mastic sealing strand. Place boiler section in front of both

inserted nipples. Raise the boiler section with the inserted nipples using a flat

chisel at all times under the section feet. The inserted nipples must stand approx.

1 to 2 mm higher than the boring of the section, which is to be joined. Using a

crowbar, raise boiler section to the inserted nipples until nipple and nipple ports

mate and hold.

Inspect boring once again for any dirt deposits before fixing the pulling-up

flanges. Remove dirt deposits if necessary.

Stage 3:

To assemble boiler sections using bar pulling-up tool.

Take care during the pulling-up process that the clearance between both boiler

and section is even. If the clearance is uneven insert a flat chisel into the narrow

point and continue pulling-up until the clearance is even again.

Nipples and Nipple ports

Driving in nipple