Page 7

23/03/01

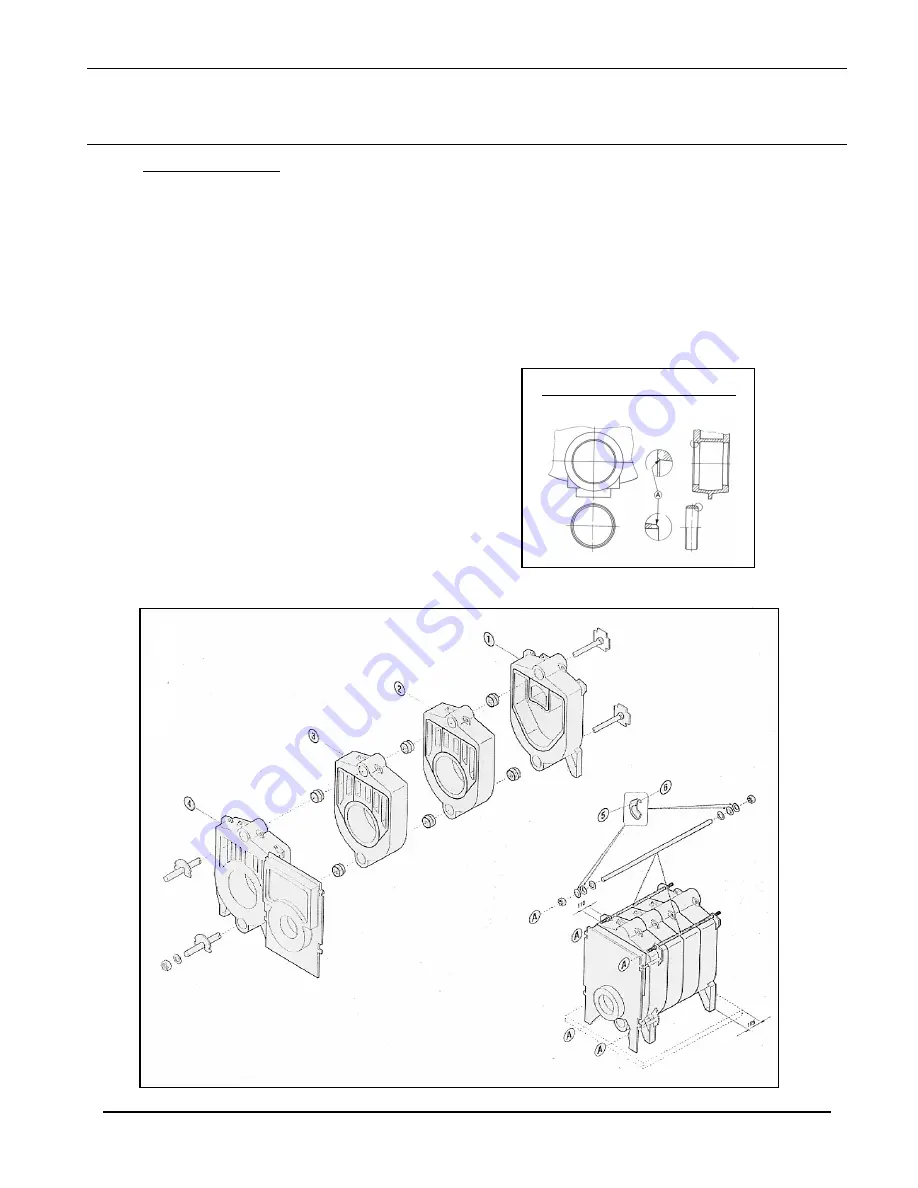

Once assembled, the boiler block is to be secured with

the tie bars (2 at the top, and 2 at the bottom). Prior to

screwing nuts up ensure the two disc springs (5)&(6)

are slotted on with concave sides facing each other.

The nuts can now be tightened until the disc springs

flatten.

The burner door hinges should now be fitted on the

left or right hand side of the front section depending

on requirements. Ensure the eyelet screws (door

hinge) are at the same depth and when the door is

closed it should press flat with the front section.

Boiler Block Assembly

The boiler block is assembled by ‘pulling-up’ each

section in turn starting from the rear section (1). All

other sections (2)(3)(4) are mounted individually

using the pulling-up tools.

One face of the adjoining sections must have a length

of mastic sealing strand placed into the mastic groove.

Each of the boiler nipples must be inspected to ensure

there is no damage apparent. The nipples and nipple

ports should then be kept free from dirt and checked

at each stage of assembly. Particles of dirt which are

not removed lead to leakage.

The accompanying nipple jointing oil serves as a

lubricant as well as a waterproof seal and must be

used.

Boiler nipples and nipple ports must align exactly at

all stages of assembly. An inclined, retracted nipple

leads to leakage.

The clearance between the sections throughout the

pulling-up stages should always be even. If the

clearance is uneven, a flat chisel should be inserted

into the narrower point and the sections pulled up

until the clearance is even again.

Diagram showing nipple & boring

ASSEMBLY INSTRUCTIONS FOR: Ca 7s / BCa 7s