Theme Plus Issue 2.1 28/06/01

Page 6 of 12

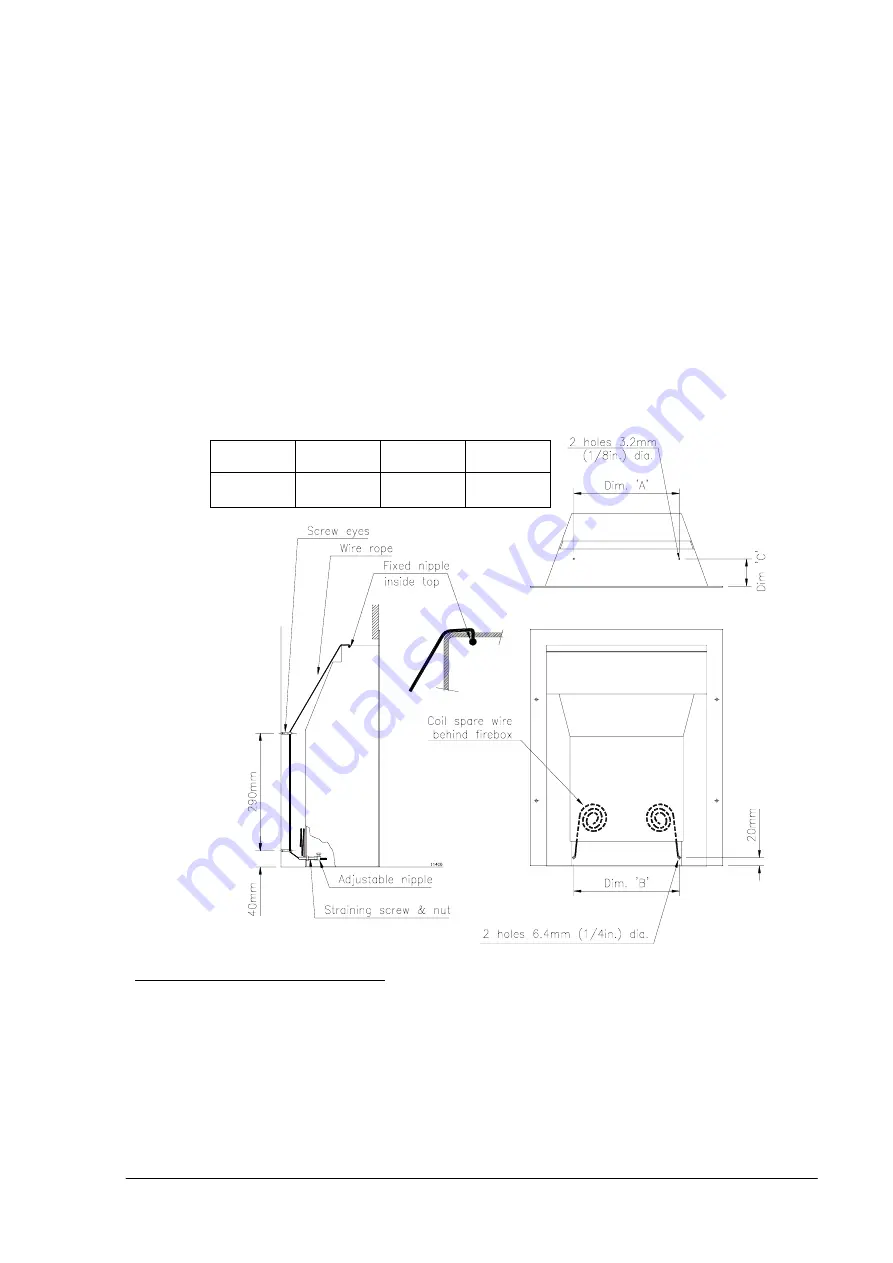

2. If the convector box has not been pre-punched for the wire ropes, drill the top and

back shown in the drawing, removing burrs from the drilled holes.

3. Pass one wire rope through each top hole, from the inside out, and pull through until

the fixed nipple rests against the inside of the top plate.

4. Place the convector box near the opening and pass each wire rope through the top

and bottom screweyes, and back through the holes in the back of the convector box.

5. Push the convector box into the opening up to the surround, pulling the wire ropes

through to take up all slack.

6. Run the backnuts up to the heads of the sleeve bolts, and thread a sleeve bolt over

each wire rope, threaded end first.

7. Push the sleeve bolts into the holes in the back of the convector box as far as the

backnuts.

8. Thread an adjustable nipple on to each wire rope up to the heads of the sleeve bolts.

Pull any slack wire through the nipple and tighten the clamp screws.

9. Make sure that the foam seal behind the fire flange is compressed all round and

then, using two spanners, screw the backnuts down the sleeve bolts in order to

tension the wire ropes and hold the convector box against the surround.

10. Coil up surplus wire rope and store inside convection channel (see drawing).

Do not

cut off surplus

; possible future removal and refitting of convector box requires the

full length of wire supplied.

Metal fluebox and flue system (Fig. 4)

Note:

The outlet restrictor plate must not be used with this installation.

1. The metal fluebox must stand on a non-combustible hearth of at least 50mm

thickness.

2. The top, sides and rear of the box must be covered with a 50mm minimum thickness

of mineral wool insulation.

3. Secure the self-adhesive foam sealing strip to the back of the convection box flange.

4. Slide the convection box into position, making sure that the sealing strip is

compressed and forms an effective seal around the complete frame.

5. Drill the front face of the opening to match the 4 holes in the flange of the appliance

and insert the plugs provided.

6. Secure the convection box using the screws provided.

Fire type

Dim. ‘A’

Dim. ‘B’

Dim. ‘C’

Theme

Plus 16”

260mm

250mm

65mm