Ecotech (Low Input) Issue 1.2 28/06/01

Page 5 of 7

Check for clearance of products of combustion

1. Light the fire.

2. Close all windows and doors.

3. After 10 minutes traverse a smoke match across the perimeter of the opening and

ensure that the smoke is drawn into the flue aperture. If spillage is detected introduce

ventilation into the room by opening a window or door. If spillage is no longer detected

then purpose made ventilation with a minimum area of 100 sq.cm must be provided. If

after introducing ventilation into the room spillage is still detected the cause must be

discovered and the fault corrected. If the fault cannot be corrected, disconnect the gas

supply to the appliance and seek expert advice. Possible causes of spillage are

chimney restrictions, or an incorrect cowl or terminal.

4. If there is an extraction fan in a nearby room then the spillage test must be repeated

with the fan turned on and any interconnecting doors between the fire and the fan

location left open.

Instruct the user

1. Hand over these Installation Instructions and the User Instructions to the person who

is going to use the fire and explain how to light and operate the appliance. Explain

how the fire may be lit, if necessary, by means of a long spill or taper.

2. Make certain that the user is aware that the ceramic blocks and coals must be located

in accordance with the instructions, and that the appliance should be serviced at

regular intervals by a competent person to ensure continued safe operation.

3. Explain that this appliance is fitted with an oxygen depletion sensor incorporated into

the pilot body. Should the fire repeatedly extinguish itself, the cause should be sought

and remedied as this may indicate spillage into the room of combustion products.

4. Indicate the tie-on warning label which the customer must remove and read.

5. Advise the user that any smell given off by the appliance will clear away after a little

use.

6. Point out that these instructions must be retained in a safe place for future use.

Maintenance

Servicing should be carried out regularly by a competent person in accordance with these

instructions and the relevant regulations, to ensure the safe and correct operation of the

appliance.

At least once a year check for debris in the flueway. If soot has accumulated ensure that the

chimney is swept clean.

Before commencing any service or replacement of parts, turn off the main gas supply

and

ensure that the fire is cold.

When ordering spare parts please quote appliance serial number which can be found on the

data badge plate.

Following a service, a check should be made for clearance of combustion products, using the

procedure detailed in these instructions.

Ceramics

Examine the coals and ceramic blocks for signs of cracking and replace if necessary. Handle

ceramic components with care. Dust off any soot or deposits with a soft brush. Do not vacuum

clean.

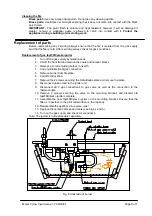

Removal of burner

To remove the burner proceed as follows:

1. Turn off the gas supply by the isolation cock.

2. Disconnect the 8mm pipe from the elbow at the left hand side of the burner.

3. Remove the 2 screws holding the burner to the hearth and lift the burner out of the

opening.

4. Reassemble in the reverse order.

5. After servicing check for gas soundness.