Ecotech (Low Input) Issue 1.2 28/06/01

Page 3 of 7

Fret options

The following Straxgas frets are suitable for use with this

appliance:

•

Black finger (brass or stainless finials &ash pan ring)

•

Brass

finger

•

Stainless finger (polished or satin)

•

Classic, Silver Classic

•

Gainsborough (all brass or black)

•

Delta (polished or satin)

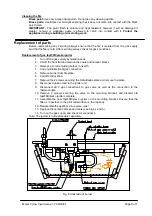

If a fret from another manufacturer is being used, it must comply

with the minimum free area requirements shown in Fig. 2.

Warning

: Only Straxgas approved ceramic blocks and coals, designed for this appliance, must

be used with this burner. Use of ceramic components from any other supplier will invalidate the

guarantee and may be dangerous.

Gas connection

Note: Gas connection is by concealed connection only. A 15mm (10mm for propane) gas supply

pipe with isolation cock

should be brought to within 1M of the fireplace opening. The connection

to the burner can be made from the right or left-hand side by a concealed pipe from behind the

burner to the elbow on the left hand side of the burner. 8mm pipe is required for this purpose.

Location

The Straxgas burner should be located as

shown in Fig.3. Locate the burner centrally

in the opening.

Securely anchor the burner in the correct

position using the screws and plastic plugs

supplied; holes are provided in the front feet

of the burner for this purpose.

Assembly

1. Connect the gas supply to the inlet elbow.

2. The ceramic components are fragile and should be handled with care. Refer to Figs. 4

and 5 for positioning of ceramic fibre blocks and coals.

3. Place the chair shaped ceramic block on the burner, pushing it back against the

upturned edge of the burner plate.

4. Place the medium sized ceramic block on the chair shaped block pushing it back to sit

comfortably between the sides of the first block.

5. Spring forward the slotted front plate and slide the front ceramic down as far as far as

the stops.

6. Remove the coals from the bag; note that there are 2 sizes supplied with the burner.

Place them on the ceramic blocks in accordance with Fig. 5.

Fig. 2 Optional fret minimum

ventilation requirement

Fig. 3

Nominal dimensions of burner

406mm (16in.)

Width of fret including posts

406mm (16in.)

Width of burner at back

254mm (10in.)

Depth from back of fret

200mm (8in.)

Back ceramic

Centre ceramic

Front ceramic

Fig. 4 Assembling the ceramic blocks

Fig. 5 Placing the loose coals