14

www.strata.co.nz

ADVANCECUT 65

5.

Direction of Cut

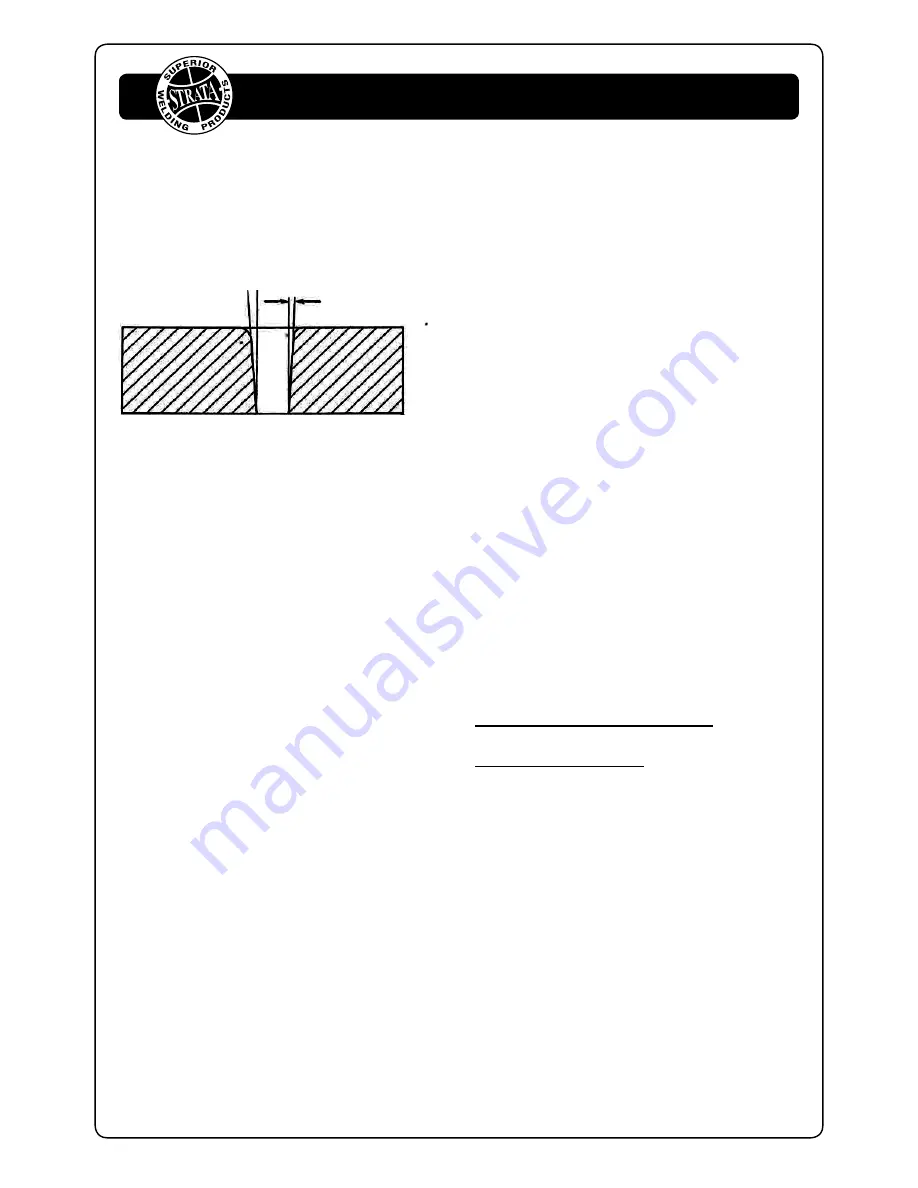

- The plasma gas stream swirls

as it leaves the torch to maintain a smooth

column of gas. This swirl effect results in one

side of a cut being more square than the other.

Viewed along the direction of travel, the right

side of the cut is more square than the left.

Left Side Cut Angle

Right Side Cut Angle

To make a square-edged cut along an inside diameter

of a circle, the torch should move counter clockwise

around the circle. To keep the square edge along an

outside diameter cut, the torch should travel in a

clockwise direction.

6. Quality Cuts

– Dross (slag) is the excess material

that spatters and builds up on the underside of the

work-piece as you cut. Dross occurs when the oper-

ating procedure and technique is less than optimal.

It will require practice and experience to obtain cuts

without dross. Although less than optimal cuts will

contain dross, it is relatively easy to remove by break-

ing it off using pliers or chipping off with a chisel or

scraping or grinding the finished cut as needed and is

generally only a minor inconvenience.

A combination of factors contributes to the build-up

of dross. They include; material type, material thick-

ness , amperage used for the cut, speed of the torch

across the work-piece, condition of the torch tip, in-

put line voltage, air pressure, etc. Generally there is

an inversely proportional relationship between output

current and speed of cut. Do not use more output cur-

rent than is necessary and adjust speed of cut toward

minimizing dross build-up on underside of cut. Ex-

periment with adjusting current and speed to mini-

mize dross.

When dross is present on carbon steel, it is common-

ly referred to as either ‘high speed, slow speed, or top

dross’. Dross present on top of the plate is normally

caused by too great a torch to plate distance.

‘Top dross’ is normally very easy to remove and can

often be wiped off with a welding glove. ‘Slow speed

dross’ is normally present on the bottom edge of the

plate. It can vary from a light to heavy bead, but does

not adhere tightly to the cut edge, and can be easily

scraped off. ‘High speed dross’ usually forms a nar-

row bead along the bottom of the cut edge and is very

difficult to remove. When cutting troublesome steel,

it is sometimes useful to reduce the cutting speed to

produce ‘slow speed dross’. Any resultant clean up

can be accomplished by scraping, not grinding.

Other Knowledge

& Resources

Please refer to Euroquip website

www.euroquip.co.nz/ Downloads.html

for knowledgebase articles & operation videos.