STIHL 029, 039

68

11.6.

Automatic Choke

11.6.1

Description of Operation

Schematic

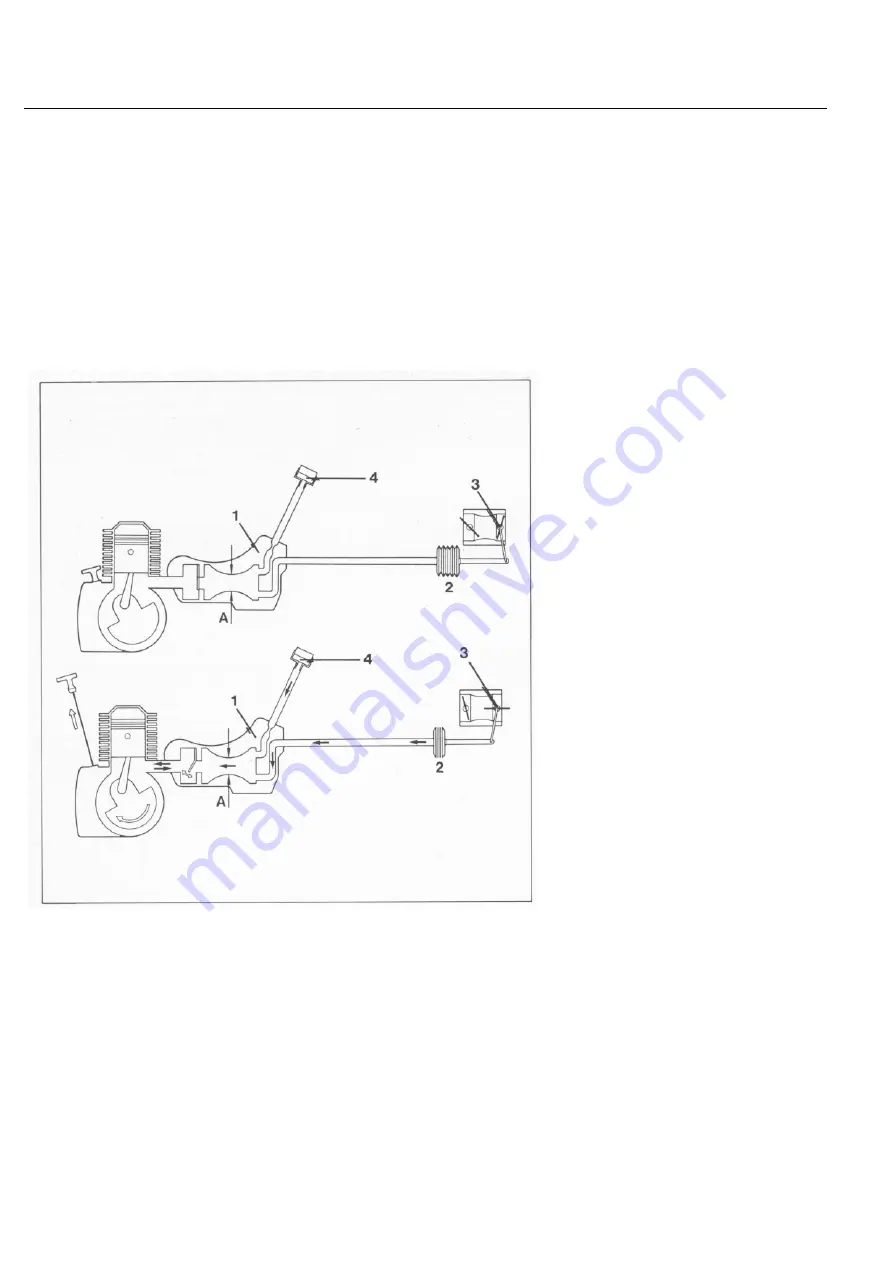

1 = Control valve

2 = Bellows

3 = Choke shutter

4 = Sintered polymer and foam filter

A = Variable cross section

The bellows are located in the

handle housing. The period for

which the belows open the choke

shutter depends on cylinder tem-

perature. It varies between 3.5

seconds on a cold engine to approx.

0.1 seconds on a hot engine.

A system of levers connects the

choke shutter to the throttle shutter.

The throttle shutter is at an angle of

37 degrees to the carburetor

mounting flange just before the choke

shutter opens fully. The throttle

shutter returns to the idle position

when the choke shutter is fully open.

Following a starting attempt, the

bellows are filled with air from the

carburetor box and returned to the

neutral position. The air required to

pressurize the bellows is drawn in

from the carburetor box via a foam

filter, a polymer sintered filter, a hose

and control valve.

The pressurizing process is ac-

companied by a low whistling noise.

The polymer sintered filter and

foam filter are located in the area of

the handle housing.

A depression is maintained in the

bellows while the engine is running,

i.e. the bellows are contracted; the

choke shutter is open.

The regular changes in pressure

which occur in the engine housing

are used to operate the automatic

choke.

These variations in pressure are fed

via a cutout in the engine housing

and through a port in the cylinder to

the control valve.

The control valve feeds the low

pressure waves at a predetermined

interval to the bellows, which

contract and thus open the choke

shutter.

The automatic choke selects the

throttle and choke shutter positions

required for an optimum mixture.

It uses the cylinder temperature as a

parameter. Cross section "A" is

changed as a function of cylinder

temperature. This, in turn, alters the

time required to vent the bellows and

thus the opening speed of the choke

shutter.