page 46

Release 00 - 03/2018

Engine TRE 224

Workshop Manual

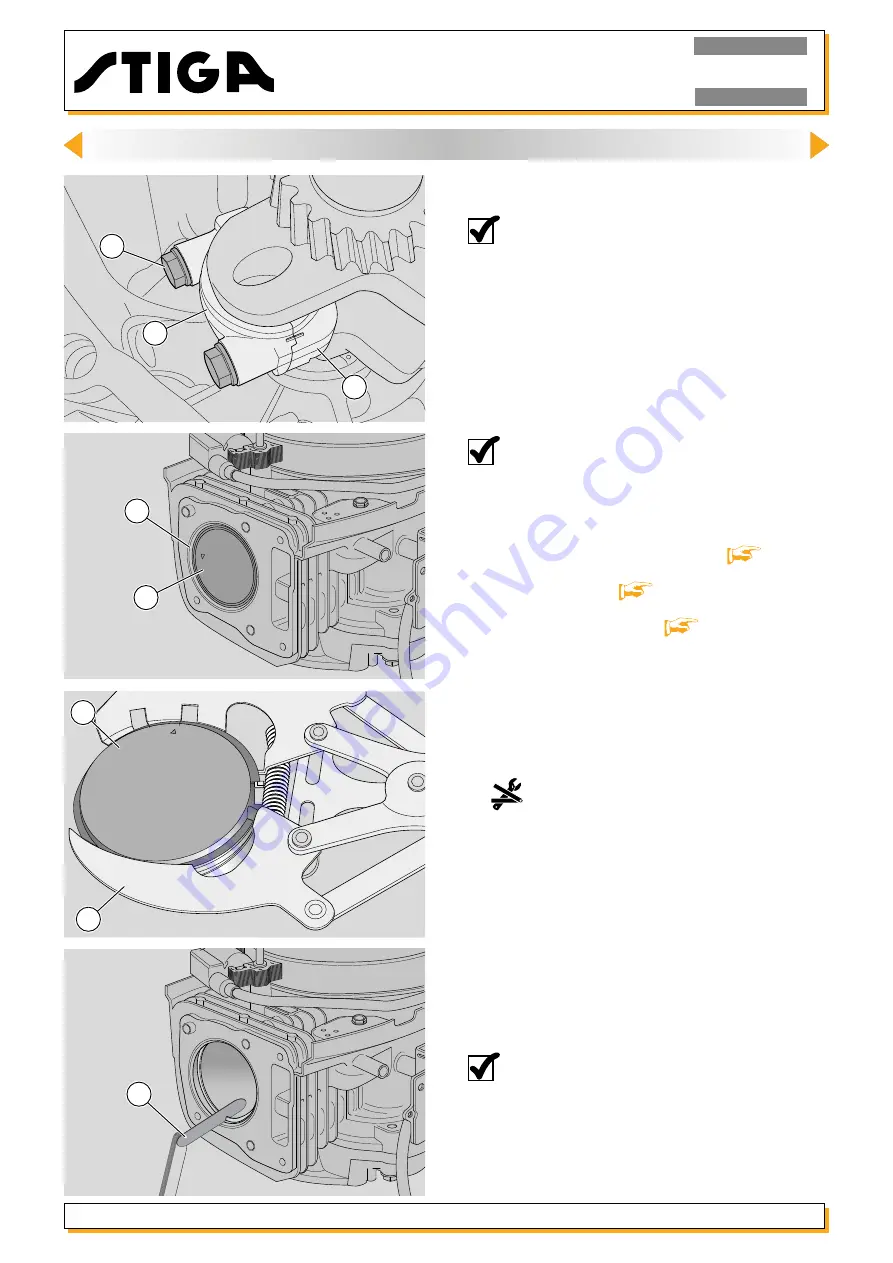

15.3. Dismantling and checking the piston, piston

rings, connecting rod and engine shaft

NOTA: These paragraphs describe all the

operations for checking and overhauling the

thermal components of the engine; it is left

to the operator to assess the advisability of

performing all the operations described or

only part of them, depending on the type of

engine problems encountered.

All the following operations on the grass cutter ne-

cessitate the removal of the motor.

NOTE: For engine removal operations you

should consult the manual specific to

the machine on which the engine itself is

mounted.

1 - Remove the magneto flywheel

.

3 - Remove the camshaft

4 - Dismantle the cap (16) of connecting rod (17)

fixed with two screws (18) (take note of any refe-

rence marks for refitting).

5 - Push the connecting rod (17) so as to cause the

piston (19) to come out of the cylinder (20).

6 -

Use the special expanding tool (21) to re-

move the two compression rings and the oil scraper

ring from the piston (19).

7 - Carefully remove all carbon deposits from the

compression rings, the inside of the cylinder and

the piston head.

8 - To check the wear in the compression rings, insert

them one at a time into the cylinder (20) by about

10-15 mm and measure the gap between the two

ends with a feeler gauge (22); the rings must be

replaced if the gap is more than 1 mm.

NOTE: If a gap of more than 0.6 mm is measu-

red with new rings it means that the cylinder is

worn beyond the acceptable limits and must

be replaced. The cylinder must be replaced

if it shows striping due to a seizure.

15. ENGINE BLOCK - Overhauling internal parts

18

17

16

21

19

19

20

22

<< BACK >>

INDEX