Release 00 - 03/2018

Engine TRE 224

page 49

Workshop Manual

15. ENGINE BLOCK - Overhauling internal parts

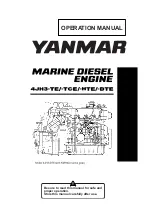

16 - To check the alignment between the mani-

folds and the protruding part of the shaft, place

the engine shaft on two prismatic guides (28) and,

with the help of a comparator (29) placed at the

end, check the displacement by rotating the shaft.

The shaft must be replaced if the displacement

exceeds 0.10 mm.

IMPORTANT: A bent shaft must never be re-

paired!

WARNING - DANGER: A bent shaft causes ab-

normal vibrations and could be dangerous

when the machine is used!

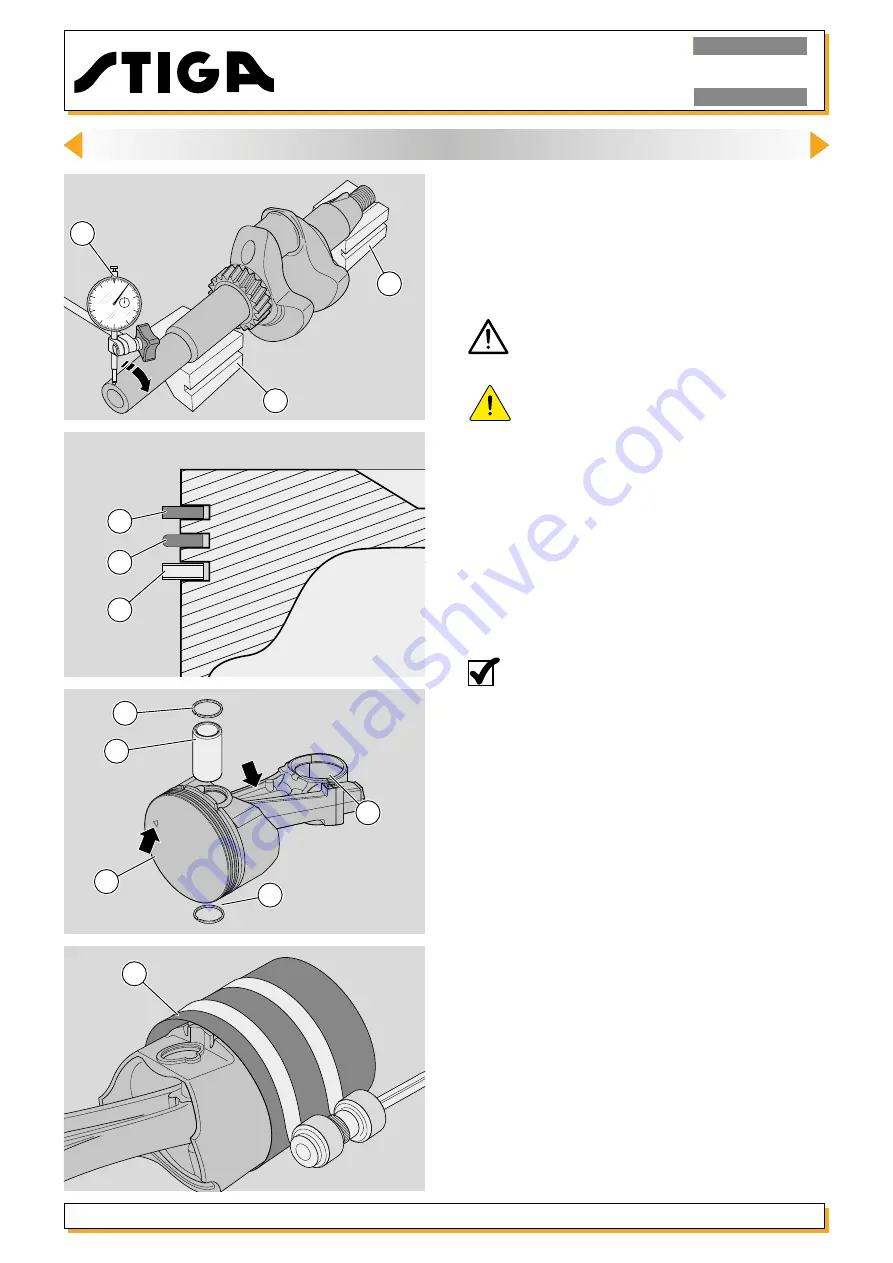

17 - To reassemble the segments on the piston per-

form sequentially:

- Mount the oil wiper (30), composed of three

rings;

- Assemble the rounded edge segment (31) with

the rounded edge facing downwards;

- Assemble the live edge segment (32).

NOTE: The two segments (31) and (32) must

be oriented with the lights not aligned betwe-

en them.

18 - Fit the connecting rod (17), the gudgeon pin

(26) and clamping rings (25) to the piston (19), ta-

king care over the connecting rod marking, which

must be pointing towards the engine shaft exit.

Piston marking must point towards the exhaust.

19 - Put the piston into the ring compression tool (33).

30

31

32

26

25

19

25

17

10

20

30

40

50

60

70

80

90

29

28

28

33

<< BACK >>

INDEX