Release 00 - 03/2018

Engine TRE 224

page 29

Workshop Manual

11. IGNITION

11.1. Checking the efficiency of the ignition system

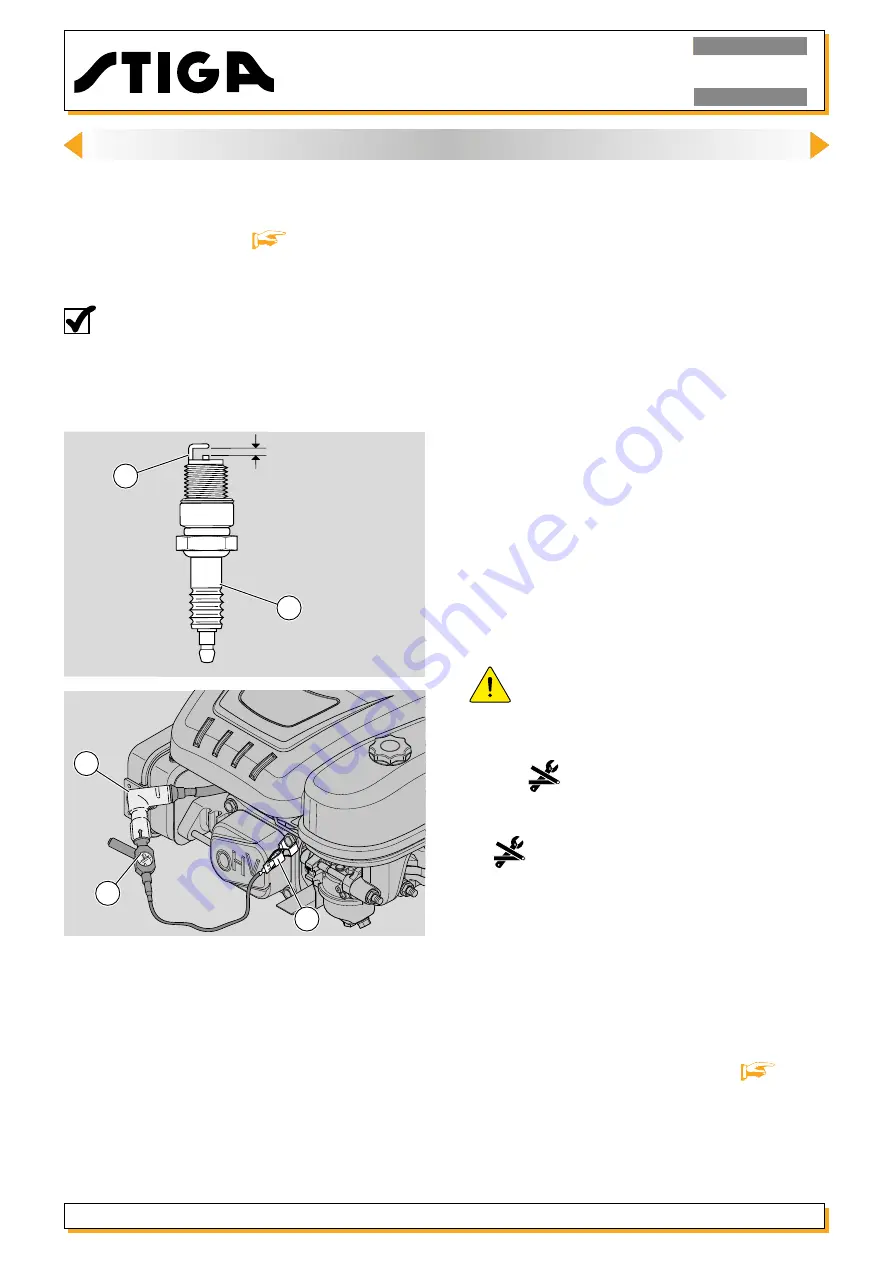

1 - Dismount the spark plug (1) and look at the co-

lour on the end of the thread. This can give you a

good idea of the carburation:

- black: mixture too greasy due to clogged air filter;

-

nut brown:

regular carburation.

Replace the spark plug (with one of the same or

equivalent characteristics)

if the electrodes (2) are

burnt or if the porcelain is broken or cracked.

FIRE HAZARD:

- do not check the ignition system if the spark

plug is not screwed in place;

- always use the specific tool for the

spark test.

2 -

Connect the tester (3) to the spark plug

cap (4) and to earth on the engine (5). Activate the

starter and see in the instrument if the spark jumps.

3 - If the test has a positive result, clean the electro-

des (2) with compressed air and adjust the distance

to 0.6-0.8 mm. Remount the spark plug and tighten

it to the specified levels.

Unless otherwise required, proceed to verify system

components as indicated in section

.

0,6 - 0,8 mm

2

1

General information

The ignition system has a flywheel with an electronic coil which supplies high voltage to the spark plug.

for advice on resolving problems related to the ignition.

The coil and magneto flywheel are accessible by removing the cover.

NOTE: For engine removal operations you should consult the manual specific to the machine on which

the engine itself is mounted.

3

5

4

<< BACK >>

INDEX