Installing The Heater

(cont'd)

12

Step 13

Connect the brown thermocouple lead wire (79) in the wiring harnesses to the core temperature

sensor (68). The yellow wire of the thermocouple lead attaches to the screw stud marked with a

yellow dot. The red wire attaches to the screw stud marked with a red dot.

The brown thermocouple lead wire must be routed in a fashion that ensures it

will be protected from physical damage and does not come into contact with any

live electrical connections in the limit bar area. Incorrect polarity on the core

temperature sensor will cause the furnace to continue to charge, even when a

high charge level has been achieved.

Step 14

Carefully install the limit bar channeling plate (61) to provide air seal around wiring harnesses

(65 & 70).

Step 15

Install the limit bar louvre panel (63).

BRICK LOADING

Step 1

Remove the sheet metal screws around the outer edge of the galvanized front panel (12) and set the

panel aside.

Step 2

Carefully lift the three insulation blankets (3, 4, & 5), one at a time, and drape them over the top of

the furnace.

Use face mask, gloves, and long sleeved garments when handling insulation

materials in accordance with generally accepted safety practices.

Step 3

Remove the aluminized steel panel (10) by pulling out at the top.

Step 4

Remove the heating elements (17) and the packing material from the brick core cavity. To ensure

adequate room for brick loading, the top or bottom 1" x 4" (nominal) wooden core spacer can be used

to hold inner brick cavity walls apart.

The core spacer is packaging material and can be discarded after brick loading

is complete.

Step 5

To minimize the amount of brick debris falling into the core blower, place the cardboard packaging

material found inside the brick cavity over the core blower opening.

Step 6

Load the brick (15), one row at a time, starting at the back working forward. Below is a list of

installation tips to aid in the brick loading process:

¢

Be sure to remove loose

brick debris as the furnace

is being loaded to prevent

uneven stacking of the

bricks.

¢

Use the half brick (boxes

marked) in the proper rows

and in the correct positions.

The half bricks should be

loaded in rows 4 and 8 in the

DLF30 and in rows 5 and 10 for the DLF40, with row 1 being at the bottom. (See Figure 6 for

the correct position of the half bricks.)

The purpose of the half brick is to make brick loading easier by evening out the

stacking. From an operation perspective, it is not essential they be placed in the

rows recommended for each model. The rows recommended simply make for the

best fit.

5

NOTE

NOTE

NOTE

NOTE

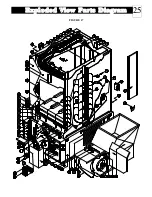

FIGURE 6

ELEMENT TERMINATION

HALF BRICK

DLF 30: LOAD IN ROWS 4 AND 8

DLF 40: LOAD IN ROWS 5 AND 10