12

15.

ALWAYS

wear eye protection. The operation of any

drum sander can result in debris being thrown into

your eyes, causing severe eye damage. Everyday

glasses are not safety glasses. Wear safety glasses

that comply with ANSI standard Z87.1

16.

KEEP

hands and clothing away from the rotating

drum, belts and pulleys.

NEVER

place hands under

the drum or dust cover.

17.

ALWAYS

feed workpieces against the rotation of

the drum.

18.

HOLD

workpieces firmly and be aware of the

possibility of kickback.

19.

DO NOT

make passes deeper than recommended

in the specifications to avoid damage to the

machine.

20.

NEVER

operate the machine without the dust cover

and belt guard in position.

21.

ALWAYS

stand to one side of the workpiece;

NEVER

stand directly in line with it.

22.

NEVER

force the workpiece into the sander; allow

the feed belt to move the workpiece at the proper

speed.

23.

MAKE SURE

that the workpiece has no loose

knots, screws, nails or other foreign objects that

might damage the feed belt or sanding drum.

24.

ALWAYS

keep bystanders and yourself away from

the infeed and outfeed ends when a workpiece is

fed into the sander.

25.

ALWAYS

keep your hands away from the sanding

drums during operation.

26.

ALWAYS

keep fingers away from the conveyor and

the underside of the workpiece during sander and

conveyor operation.

27.

ALWAYS

adjust the conveyor feed rate and sand-

ing drum height, so when you feed the workpiece

into the sander using light pressure, you do not

overload the sander.

NEVER

force the workpiece

into the sander.

28.

ALWAYS

shut the sander down, let the drums

come to a complete stop, and disconnect power or

engage applicable safety-lock devices before you

service, adjust, troubleshoot, or leave the machine

unattended.

29.

ALWAYS

keep this machine in correct adjustment

and properly serviced.

NEVER

attempt to clear a

jammed workpiece while the sander is running.

30.

ALWAYS

replace the sandpaper when it is worn,

and use only undamaged sandpaper.

31.

NEVER

sand if there is any doubt about the

stability or integrity of the workpiece.

32.

NEVER

sand stock smaller than 1/4” thick or

6” long.

33.

NEVER

adjust the conveyor belt tracking when the

sanding drums are engaged.

ELECTRICAL REQUIREMENTS

To reduce the risk of electric shock, follow all electri-

cal and safety codes, including the National Electric

Code (NEC) and the Occupational Safety and Health

Regulations (OSHA). All electrical connections and

wiring should be made by qualified personnel only.

The switch provided with your dual drum sander is

designed to plug in to a 230V outlet. Since there are

many different configurations for 230V plugs, it is con-

ceivable that the configuration of your 230V outlet may

not match the configuration of the plug. If this is the

case, you will have to replace the plug with a UL/CSA

approved plug that matches the configuration of your

230V outlet.

DO NOT

connect the machine to the power source until

you have completed the setup process.

WARNING

!

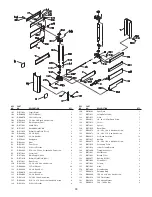

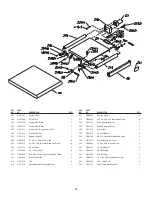

Summary of Contents for 55220

Page 28: ......