7

OPERATION

MAINTENANCE

EN

OPERATION

SWITCHING ON - SWITCHING OFF

Brief activation:

•

Switching on: press the ON/OFF switch lever 1.

•

Switching off: Release ON/OFF switch 1.

Continuous operation:

•

Switching on: With the machine switched on press the locking button 7 and release the

ON/OFF switch lever 1.

•

Switching off: Press ON/OFF switch 1 once and release it immediately.

Preselecting the speed

•

To set the operating speed, move the dial 2 to the required value.

MOUNTING THE AUXILIARY HANDLE

•

The auxiliary handle 3 is fastened to the gear box by two bolts under the bolt heads.

Screwing and unscrewing the bolts is performed by an open end spanner.

•

The auxiliary handle 4 can be mounted alternatively to the right or left side of the gear

box. It is screwed directly to the machine gear box.

BACKING PAD

•

The backing pad 5 can be screwed directly onto the spindle. The hook-and-loop

operating tools 6 (sandpaper, polishing sponge, felt wheel, lambswool bonnet, etc.)

can be fixed directly onto the backing pad.

•

To dismount (unscrew) the backing pad use a spanner when necessary.

FIXING THE OPERATING TOOL TO THE HOOK-AND-LOOP (VELCRO) BACKING PAD

•

The operating tool fastened to the backing pad shall be Ømin148. The operating tool

shall be aligned with the backing pad and care shall be taken to ensure their coaxiality.

Eccentrically mounted operating tools cause wobbling and vibrations.

•

WARNING:

Use only pads with un-damaged hook-and-loop system. Perform a trial test

for at least 30 sec at no load after replacing the backing pad.

•

WARNING:

Vibrating or otherwise improperly rotating backing pads must be re-placed

immediately!

Summary of Contents for PA150CE

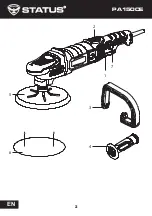

Page 2: ...2 PA150CE EN 5 3 4 6 1 7 2 ...

Page 40: ......