7

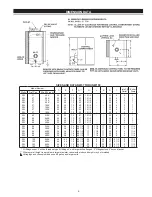

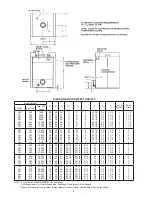

dIMensIon data (cont’d)

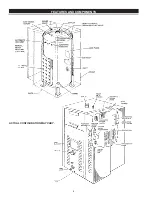

BoIler specIfIcatIons (standard)

Model Number

BTU

Output

Gal./Hr.

100°F

Rise

Number

of

Elements

Number

of Steps

*

Standard Number and

KW of Steps

*

Amperage 3 Phase

Prefix

Gal. Cap.

Std. KW

Input

208V

240V

480V

575V

SW

SW

SW

SW

SW

SW

SW

SW

37

37

37

37

37

37

37

37

45K

60K

75K

90K

105K

120K

150K

180K

153,585

204,720

255,975

307,170

358,365

409,560

511,950

614,340

180

240

300

369

430

492

615

738

3

4

5

6

7

8

10

12

1

1

1

3

4

4

5

6

1@45

1@60

1@75

3@30

3@30+1@15

4@30

5@30

6@30

128

171

213

250

292

334

417

500

108

144

180

217

253

289

361

433

55

73

90

108

126

144

180

216

45

60

75

90

105

121

151

181

SW

SW

SW

SW

60

60

60

60

210K

240K

270K

300K

716,730

819,120

921,510

1,023,900

861

984

1107

1230

14

16

18

20

7

8

9

10

7@30

8@30

9@30

10@30

584

668

751

834

505

577

650

722

252

288

324

360

211

241

271

301

SW

SW

SW

SW

SW

SW

96

96

96

96

96

96

330K

360K

390K

420K

450K

480K

1,126,290

1,228,680

1,331,070

1,433,460

1,535,850

1,638,240

1353

1476

1599

1722

1845

1968

22

24

26

28

30

32

10

10

10

10

10

10

1@60+9@30

2@60+8@30

3@60+7@30

4@60+6@30

5@60+5@30

6@60+4@30

917

1001

1084

1168

1251

1334

794

866

938

1010

1083

1155

396

432

468

504

540

576

331

362

392

422

452

487

SW

SW

SW

SW

150

150

150

150

540K

600K

660K

720K

1,843,020

2,047,800

2,252,580

2,457,360

2214

2460

2706

2952

36

40

44

48

10

10

10

10

8@60+2@30

10@60

8@60+2@90

4@90+6@60

1501

1668

1299

1443

648

720

792

864

542

602

663

723

SW

SW

SW

SW

SW

SW

SW

220

220

220

220

220

220

220

780K

840K

900K

960K

1020K

1080K

1140K

2,662,140

2,866,920

3,071,700

3,276,480

3,481,260

3,636,040

3,890,820

3198

3444

3690

3936

4182

4428

4674

52

56

60

64

68

72

76

10

10

10

10

10

10

10

6@90+4@60

9@90+1@30

10@90

8@90+2@120

6@90+4@120

4@90+6@120

2@90+8@120

936

1008

1080

1152

1224

1296

1368

783

843

904

964

1024

1084

1145

SW

SW

SW

SW

SW

SW

334

334

334

334

334

334

1200K

1260K

1380K

1500K

1620K

1740K

4,095,600

4,300,380

4,709,940

5,119,500

5,529,060

5,938,630

4920

5166

5658

6150

6642

7134

80

84

92

100

108

116

10

10

10

10

16

17

10@120

8@120+2@150

4@120+6@150

10@150

10@90+6@120

10@90+7@120

1440

1512

1656

1800

1944

2068

1205

1265

1386

1506

1627

1747

SW

SW

SW

SW

400

400

400

400

1800K

1860K

1980K

2100K

6,143,400

6,348,180

6,757,740

7,167,300

7380

7626

8118

8610

120

124

132

140

17

17

18

19

8@90+9@120

6@90+11@120

6@90+12@120

6@90+13@120

2160

2232

2376

2520

1807

1868

1988

2109

SW

SW

SW

SW

500

500

500

500

2220K

2340K

2460K

2580K

7,576,860

7,986,420

8,395,980

8,805,540

9102

9594

10080

10578

148

156

164

172

15

20

20

20

1@120+14@150

18@120+2@90

18@120+2@150

14@120+6@150

2664

2808

2952

3096

2229

2350

2470

2590

SW

SW

SW

670

670

670

2700K

2820K

2940K

9,315,100

9,624,660

10,034,220

11070

11562

12054

180

188

196

20

20

20

10@120+10@150

6@120+14@150

2@120+18@150

3240

3384

3528

2711

2832

2952

NOTE: For boilers 3000KW to 6000KW consult factory.

*Consult factory for optional number of steps and Kw per step.