12

14

7

4

Instruction manual

6

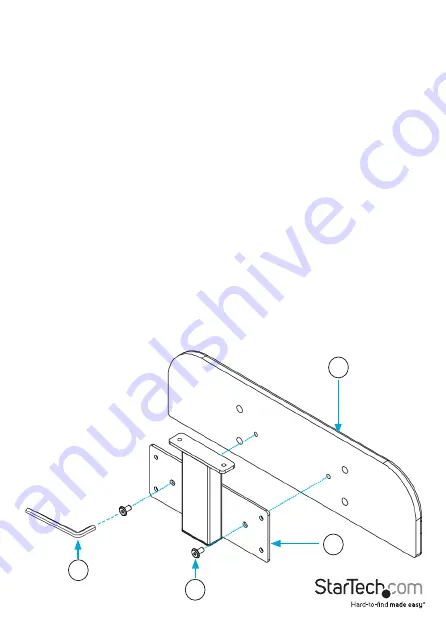

Attach the keyboard tray backing to the mounting pillar

1. Line up the single hole on each side of the mounting pillar (

7

) with the

corresponding holes on the keyboard tray backing (

4

).

2. Use the M4*55 Allen wrench (

12

) to insert two M6*12 screws (

14

) into the mounting

pillar and then the keyboard tray backing.

3. Turn the Allen wrench clockwise to tighten the screws.

Warning!

Do not over-tighten the screws. (tightening torque is 1.5 Nm)

Warning!

When lowering or raising the workstation, ensure the mounted equipment

is properly secured or supported and the speed is slow enough to prevent any

equipment instability. Failure to do so may result in property damage and/or personal

injury.

Attach the pneumatic arm to the workstation

1. Line up the two holes on each of the brackets of the pneumatic arm (

1

) with four of

the holes on the workstation (

5

).

2. Use the M4*55 Allen wrench (

12

) to insert four M6*12 screws (

14

) into the two holes

on each side of the bracket on the pneumatic arm and into the workstation.

3. Turn the Allen wrench clockwise to tighten the screws.

4. Out of the box, the lever is tucked into the pneumatic arm. Pull the lever out from

the pneumatic arm, and then use the M4*55 Allen wrench to insert two M6*12

screws through the holes on the sides of the lever and into the workstation.

5. Turn the Allen wrench clockwise to tighten the screws.

Warning!

Do not over-tighten the screws. (tightening torque is 1.5 Nm)