-

32

-

8. Maintenance

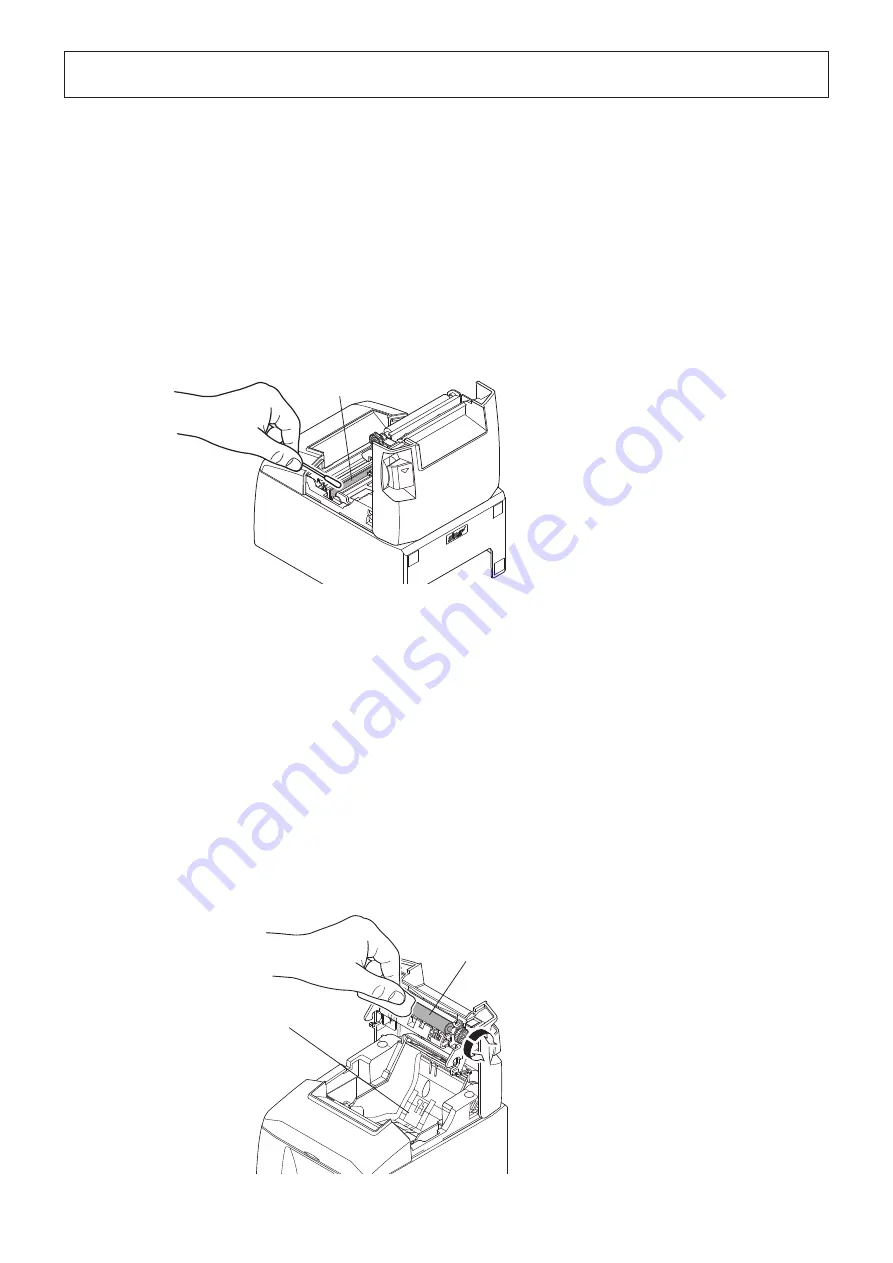

Thermal head

Rubber roller

Paper holder

Accumulation of paper dust and dirt may cause the printer to not print portions of characters.

To prevent such problems, perform periodic maintenance, such as removing paper dust from the paper transport sec-

tion and removing the blackened paper dust from the thermal head surface.

As a guideline, clean the printer every six months.

Note: Turn the printer’s power switch off before performing maintenance.

8-1. Thermal Head

To remove the blackened paper dust that has accumulated on the thermal head surface, wipe it clean with a cotton swab

(or soft cloth) dipped in alcohol (ethanol, methanol, or isopropyl).

8-2. Platen Rubber Roller

Using a dry, soft cloth, wipe off the dirt from the rubber roller. Clean the entire rubber roller by rotating it.

8-3. Paper Holder

Clean the paper holder of debris, dust, paper particles, etc. that may have accumulated.

Note 1: The thermal head is easily damaged.

Be sure to clean the thermal head with a soft cloth, and be careful not to damage the head.

2: Do not clean the thermal head immediately after printing, when the thermal head is hot.

3: Be careful of static electricity while cleaning the thermal head. Static electricity can damage the head.

4: Turn the power on only after the alcohol has dried completely.