5

IL1269

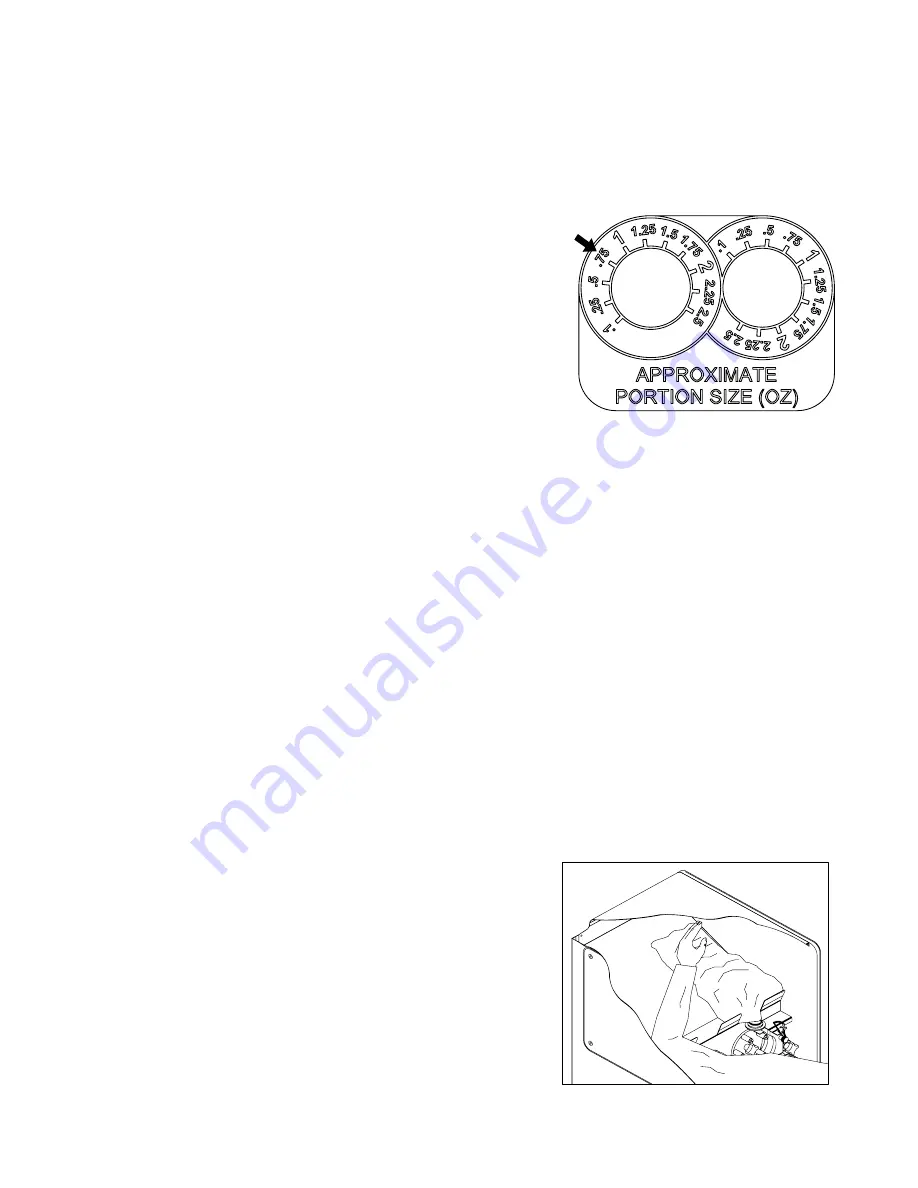

PORTION CONTROL

This dispenser is supplied with a portion control timer. This portion control is based on a time

setting. Variations in product temperature and consistency will affect the dispensed amount.

To insure a consistent portion, use product that is at the correct temperature (145°F to 160°).

SPDE2 models have a Portion Control Label showing approximate settings for portion size

in oz,

see Fig 1

. The units are pre-set at the factory for 0.75oz, this is a general guideline, and

following procedures still need to be followed to complete calibration.

IL1268

To set portion:

1. Load preheated product bag into dispenser.

2. Dispense product until there is a steady fl ow.

3. Dispense the product into a clean container and

measure the product to verify the dispensed

amount.

4. Using a small screwdriver, remove the round plug

covering the adjustment knob located on the front

of the unit below the tube cover.

5. Turn the control dial clockwise for more product

and counterclockwise for less product.

6. Repeat steps 3 and 5 until the desired amount

is reached.

OPERATION NOTES

The product should be preheated according to the manufacturer's instructions.

The product should be a minimum of 140°F before dispensing.

The digital temperature readout displays the cabinet air temperature and will fl uctuate during

normal operation. The product temperature should be close to the temperature set point, but

the actual product temperature should be checked periodically to ensure proper operation.

The dispenser will not function correctly if the product is not at the correct temperature.

CHECKING PRODUCT TEMPERATURE

The dispenser should be plugged in and turned on with product in the dispenser for a least 5

hours.

1. Dispense at least 3 inches of product into an insulated cup.

2. Without hesitation, insert the thermometer to the bottom of the cup and stir the product

gently with the stem of the thermometer.

3. Position the tip of the thermometer in the center of the product mass.

4. The temperature should read between 140°F and 160°F.

The dispenser is designed to operate 24 hours a day. Once the product is placed in the

dispenser it should not be removed until the bag is empty or the holding period of the product

has expired.

NOTE:

To increase the evacuation,

open the dispenser and pull the

product toward the outlet 3 or 4 times

during operation,

see Fig 2

.

Figure 1, Portion Control Label,

SPDE2 models only.

Figure 2, Pull product down once or

twice during operation.